Product Description

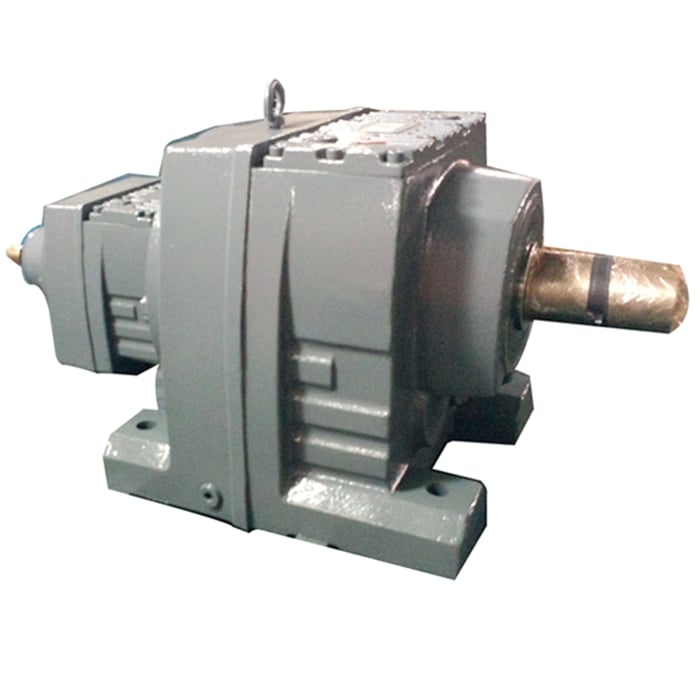

Tractor Rotary Mowers Bevel Fertilizer Spreader Tillers Right Angle Pto Shaft Reducer Gearbox for Farm and Agricultural Machinery

Established in Nov.2002,HangZhou CHINAMFG is a professional manufacturer and supplier in supplying spare parts and accessories for agricultural machinery. In addition to the 3000 standards parts, we also offer our customers tailor-made articles or assemblies that are for special application.

HangZhou CHINAMFG focused on the development and production of gearboxes with a professional team and continue to learn advanced technology; the use of first-class equipment; high quality supply chain system, relying on these, the gearboxes get high reputation among customers at home and abroad.

These gearboxes are widely used in rotary tillers, lawn mowers, harvesters, hole diggers, pesticide sprayers, irrigation machines, fertilizer spreaders, blenders and so on. The main products are:

–Straight bevel gearbox

–Spiral bevel gearbox

–Planetary reducer

–Worm gearbox

HangZhou CHINAMFG International Trading Co.,Ltd is a modern enterprise specilizing in the development, production, sales and services of PTO shaft. We adhere to the principle of “Precise Driveline, Advocate Green”, using advanced technology and equipments to ensure all the technical standards of precise driveline. So that the transmission efficiency can be maxmized and every drop of resource of customers’ can be saved. Meanwhile, we have a customer-centric service system, providing a full range of pre-sale, sale and after-sale service. Customer satisfaction is our forever pursuit.

We follow the principle of people first, trying our best to set up a pleasant surroundings and platform of performance for each employee, so everyone can be self-consciously active to join in “Precise Driveline, Adocate Green” to embody the self-worth, enterprise value and social value.

Newnuro’s goal is: reducing customer’s purchase budget, support customers to earn more market.

Newnuro always finds solution for customers.Customer satisfaction is our ultimate goal and forever pursuit.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Assembled |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Single-Step |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What maintenance practices are essential for prolonging the lifespan of PTO shafts?

Maintaining proper care and performing regular maintenance on Power Take-Off (PTO) shafts is crucial for prolonging their lifespan and ensuring optimal performance. By following essential maintenance practices, you can prevent premature wear, identify potential issues early on, and maximize the longevity of your PTO shafts. Here are some key maintenance practices to consider:

1. Regular Inspection: Perform routine visual inspections of the PTO shaft to check for any signs of damage, wear, or misalignment. Look for cracks, dents, bent sections, or loose components. Inspect the universal joints, coupling mechanisms, protective guards, and other associated parts. Pay attention to any unusual noises, vibrations, or changes in performance, as these can indicate underlying issues that require attention.

2. Lubrication: Proper lubrication is essential for the smooth operation and longevity of PTO shafts. Follow the manufacturer’s recommendations regarding lubrication intervals and use the recommended lubricant type. Apply lubrication to the universal joints, CV joints (if applicable), and other moving parts as specified. Regularly check for adequate lubricant levels and replenish if necessary. Ensure that the lubricant used is compatible with the shaft material and does not attract dirt or debris that could cause abrasion or damage.

3. Cleaning: Keep the PTO shaft clean and free from dirt, debris, and other contaminants. Regularly remove any accumulated dirt, grease, or residue using a brush or compressed air. Be particularly diligent in cleaning the universal joints and areas where the shaft connects to other components. Cleaning prevents the buildup of abrasive particles that can accelerate wear and compromise the shaft’s performance.

4. Guard Inspection and Maintenance: Check the protective guards and shields regularly to ensure they are securely in place and free from damage. Guards play a critical role in preventing accidental contact with the rotating shaft and minimizing the risk of injury. Repair or replace any damaged or missing guards promptly. Ensure that the guards are correctly aligned and provide sufficient coverage for all moving parts of the PTO shaft.

5. Torque and Fastener Checks: Periodically inspect and check the torque of fasteners, such as bolts and nuts, that secure the PTO shaft and associated components. Over time, vibration and normal operation can loosen these fasteners, compromising the integrity of the shaft. Use the appropriate torque specifications provided by the manufacturer to ensure proper tightening. Regularly verify the tightness of fasteners and retighten as necessary.

6. Shear Bolt or Slip Clutch Maintenance: If your PTO shaft incorporates shear bolt or slip clutch mechanisms, ensure they are functioning correctly. Inspect the shear bolts for signs of wear or damage, and replace them when necessary. Check the slip clutch for proper adjustment and smooth operation. Follow the manufacturer’s recommendations regarding maintenance and adjustment of these safety mechanisms to ensure their effectiveness in protecting the driveline components.

7. Proper Storage: When the PTO shaft is not in use, store it in a clean and dry environment. Protect the shaft from exposure to moisture, extreme temperatures, and corrosive substances. If possible, store the shaft in a vertical position to prevent bending or distortion. Consider using protective covers or cases to shield the shaft from dust, dirt, and other potential sources of damage.

8. Operator Training: Provide proper training to operators on the correct operation, maintenance, and safety procedures related to the PTO shafts. Educate them about the importance of regular inspections, lubrication, and adherence to recommended maintenance practices. Encourage operators to report any abnormalities or concerns promptly to prevent further damage and ensure timely repairs or adjustments.

9. Manufacturer and Expert Guidance: Consult the manufacturer’s guidelines and recommendations regarding maintenance practices specific to your PTO shaft model. Additionally, seek advice from experts or authorized service technicians who are knowledgeable about PTO shaft maintenance. They can provide valuable insights and assistance in implementing the best maintenance practices for your specific PTO shafts.

By following these maintenance practices, you can extend the lifespan of your PTO shafts, optimize their performance, and reduce the likelihood of unexpected failures or costly repairs. Regular inspections, lubrication, cleaning, guard maintenance, torque checks, and proper storage are all essential in ensuring the longevity and reliability of your PTO shafts.

How do PTO shafts handle variations in load and torque during operation?

PTO (Power Take-Off) shafts are designed to handle variations in load and torque during operation by employing specific mechanisms and features that ensure efficient power transfer and protection against overload conditions. Here’s a detailed explanation of how PTO shafts handle variations in load and torque:

1. Mechanical Design: PTO shafts are engineered with robust mechanical design principles that enable them to handle variations in load and torque. They are typically constructed using high-strength materials such as steel, which provides durability and resistance to bending or twisting forces. The shaft’s diameter, wall thickness, and overall dimensions are carefully calculated to withstand the expected torque levels and load variations. The mechanical design of the PTO shaft ensures that it can transmit power reliably and accommodate the dynamic forces encountered during operation.

2. Universal Joints: Universal joints are a key component of PTO shafts that allow for flexibility and compensation of misalignment between the power source and driven machinery. These joints can accommodate variations in angular alignment, which may occur due to changes in load or movement of the machinery. Universal joints consist of a cross-shaped yoke with needle bearings that allow for smooth rotation and transfer of torque, even when the shafts are not perfectly aligned. The design of universal joints enables PTO shafts to handle variations in load and torque while maintaining consistent power transmission.

3. Slip Clutches: Slip clutches are often incorporated into PTO shafts to provide overload protection. These clutches allow the PTO shaft to slip or disengage momentarily when excessive torque or resistance is encountered. Slip clutches typically consist of friction plates that can be adjusted to a specific torque setting. When the torque surpasses the predetermined limit, the clutch slips, preventing damage to the PTO shaft and connected equipment. Slip clutches are particularly useful when sudden changes in load or torque occur, providing a safety mechanism to protect the PTO shaft and associated machinery.

4. Torque Limiters: Torque limiters are another protective feature found in some PTO shafts. These devices are designed to automatically disengage the power transmission when a predetermined torque threshold is exceeded. Torque limiters can be mechanical, such as shear pin couplings or friction clutches, or electronic, utilizing sensors and control systems. When the torque exceeds the set limit, the torque limiter disengages, preventing further power transfer and protecting the PTO shaft from overload conditions. Torque limiters are effective in handling sudden spikes in torque and safeguarding the PTO shaft and associated equipment.

5. Maintenance and Inspection: Regular maintenance and inspection of PTO shafts are essential to ensure their proper functioning and ability to handle variations in load and torque. Routine maintenance includes lubrication of universal joints, inspection of shaft integrity, and tightening of fasteners. Regular inspections allow for early detection of wear, misalignment, or other issues that may affect the PTO shaft’s performance. By addressing maintenance and inspection requirements, operators can identify and address any concerns that may arise due to variations in load and torque, ensuring the continued safe and efficient operation of the PTO shaft.

6. Operator Awareness and Control: Operators play a crucial role in managing variations in load and torque during PTO shaft operation. They should be aware of the machinery’s operational limits, including the recommended torque ratings and load capacities of the PTO shaft. Proper training and understanding of the equipment’s capabilities enable operators to make informed decisions and adjust the operation when encountering significant load or torque changes. Operators should also be vigilant in monitoring the equipment’s performance, watching for any signs of excessive vibration, noise, or other indications of potential issues related to load and torque variations.

By incorporating robust mechanical design, utilizing universal joints, slip clutches, torque limiters, and implementing proper maintenance practices, PTO shafts are equipped to handle variations in load and torque during operation. These features ensure reliable power transmission, protect against overload conditions, and contribute to the safe and efficient functioning of the PTO shaft and the machinery it drives.

Which industries commonly use PTO shafts for power transmission?

PTO shafts (Power Take-Off shafts) are widely used in various industries where power transmission is required to drive machinery and equipment. Their versatility, efficiency, and compatibility with different types of machinery make them valuable components in several sectors. Here’s a detailed explanation of the industries that commonly use PTO shafts for power transmission:

1. Agriculture: The agricultural industry extensively relies on PTO shafts for power transmission. Tractors equipped with PTOs are commonly used to drive a wide range of agricultural implements and machinery. PTO-driven equipment includes mowers, balers, tillers, seeders, sprayers, grain augers, harvesters, and many more. PTO shafts allow for the efficient transfer of power from the tractor’s engine to these implements, enabling various agricultural operations such as cutting, baling, tilling, planting, spraying, and harvesting. The agricultural sector heavily depends on PTO shafts to enhance productivity and streamline farming processes.

2. Construction and Earthmoving: In the construction and earthmoving industry, PTO shafts find applications in machinery used for excavation, grading, and material handling. PTO-driven equipment such as backhoes, loaders, excavators, trenchers, and stump grinders utilize PTO shafts to transfer power from the prime movers, typically hydraulic systems, to drive the necessary attachments. These attachments require the high torque and power provided by PTO shafts to perform tasks like digging, loading, trenching, and grinding. PTO shafts allow for versatile and efficient power transmission in construction and earthmoving operations.

3. Forestry: The forestry industry utilizes PTO shafts for power transmission in various logging and timber processing equipment. PTO-driven machinery such as wood chippers, sawmills, log splitters, and debarkers rely on PTO shafts to transfer power from tractors or dedicated power units to perform tasks like chipping, sawing, splitting, and debarking wood. PTO shafts provide the necessary power and torque to drive the cutting and processing mechanisms, enabling efficient and productive forestry operations.

4. Landscaping and Groundskeeping: PTO shafts play a crucial role in the landscaping and groundskeeping industry. Equipment like lawn mowers, rotary cutters, flail mowers, and aerators utilize PTO shafts to transfer power from tractors or dedicated power units to drive the cutting or grooming mechanisms. PTO shafts enable efficient power transmission, allowing operators to maintain lawns, parks, golf courses, and other outdoor spaces with precision and productivity.

5. Mining and Quarrying: PTO shafts have applications in the mining and quarrying industry, particularly in equipment used for material extraction, crushing, and screening. PTO-driven machinery such as crushers, screeners, and conveyors rely on PTO shafts to transfer power from engines or motors to drive the crushing and screening mechanisms, as well as the material handling systems. PTO shafts provide the necessary power and torque to process and transport bulk materials effectively in mining and quarrying operations.

6. Industrial Manufacturing: PTO shafts are utilized in various industrial manufacturing processes that require power transmission to drive specific machinery and equipment. Industries such as food processing, textile manufacturing, paper production, and chemical processing may use PTO-driven machinery for tasks like mixing, blending, cutting, extruding, and conveying. PTO shafts enable efficient power transfer to these machines, ensuring smooth and reliable operation in industrial manufacturing settings.

7. Utilities and Infrastructure Maintenance: PTO shafts find applications in utilities and infrastructure maintenance operations. Equipment like street sweepers, sewer cleaners, road maintenance machines, and drain augers utilize PTO shafts to transfer power from trucks or dedicated power units to perform tasks like sweeping, cleaning, and maintenance of roads, sewers, and other public infrastructure. PTO shafts enable efficient power transmission, ensuring effective and reliable operation of these utility and maintenance machines.

8. Others: PTO shafts are also used in several other industries and sectors where power transmission is required. This includes applications in the transportation industry for powering refrigeration units, fuel pumps, and hydraulic systems in trucks and trailers. PTO shafts also find applications in the marine industry for powering winches, pumps, and other equipment on boats and ships.

In summary, PTO shafts are commonly used in a wide range of industries for power transmission. These industries include agriculture, construction and earthmoving, forestry, landscaping and groundskeeping, mining and quarrying, industrial manufacturing, utilities and infrastructure maintenance, transportation, and marine sectors. PTO shafts play a critical rolein enhancing productivity, enabling efficient operation of machinery, and facilitating various tasks in these industries.

editor by CX 2024-01-24

China wholesaler Tractor Rotary Mowers Bevel Cultivator Tillers Right Angle Pto Shaft Reducer Gearbox for Farm and Agricultural Machinery

Product Description

Tractor Rotary Mowers Bevel Fertilizer Spreader Tillers Right Angle Pto Shaft Reducer Gearbox for Farm and Agricultural Machinery

Established in Nov.2002,HangZhou CHINAMFG is a professional manufacturer and supplier in supplying spare parts and accessories for agricultural machinery. In addition to the 3000 standards parts, we also offer our customers tailor-made articles or assemblies that are for special application.

HangZhou CHINAMFG focused on the development and production of gearboxes with a professional team and continue to learn advanced technology; the use of first-class equipment; high quality supply chain system, relying on these, the gearboxes get high reputation among customers at home and abroad.

These gearboxes are widely used in rotary tillers, lawn mowers, harvesters, hole diggers, pesticide sprayers, irrigation machines, fertilizer spreaders, blenders and so on. The main products are:

–Straight bevel gearbox

–Spiral bevel gearbox

–Planetary reducer

–Worm gearbox

HangZhou CHINAMFG International Trading Co.,Ltd is a modern enterprise specilizing in the development, production, sales and services of PTO shaft. We adhere to the principle of “Precise Driveline, Advocate Green”, using advanced technology and equipments to ensure all the technical standards of precise driveline. So that the transmission efficiency can be maxmized and every drop of resource of customers’ can be saved. Meanwhile, we have a customer-centric service system, providing a full range of pre-sale, sale and after-sale service. Customer satisfaction is our forever pursuit.

We follow the principle of people first, trying our best to set up a pleasant surroundings and platform of performance for each employee, so everyone can be self-consciously active to join in “Precise Driveline, Adocate Green” to embody the self-worth, enterprise value and social value.

Newnuro’s goal is: reducing customer’s purchase budget, support customers to earn more market.

Newnuro always finds solution for customers.Customer satisfaction is our ultimate goal and forever pursuit.

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Assembled |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Single-Step |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do manufacturers ensure the compatibility of PTO shafts with different equipment?

Manufacturers employ various measures to ensure the compatibility of PTO (Power Take-Off) shafts with different equipment. Compatibility is crucial to ensure that PTO shafts can effectively transfer power from the power source to the driven machinery without compromising performance, safety, or ease of use. Here’s a detailed explanation of how manufacturers ensure compatibility:

1. Standardization: PTO shafts are designed and manufactured based on standardized specifications. These specifications outline the essential parameters such as shaft dimensions, spline sizes, torque ratings, and safety requirements. By adhering to standardized designs, manufacturers ensure that PTO shafts are compatible with a wide range of equipment that meets the same standards. Standardization allows for interchangeability, meaning that PTO shafts from one manufacturer can be used with equipment from another manufacturer as long as they conform to the same specifications.

2. Collaboration with Equipment Manufacturers: PTO shaft manufacturers often collaborate closely with equipment manufacturers to ensure compatibility. They work together to understand the specific requirements of the equipment and design PTO shafts that seamlessly integrate with the machinery. This collaboration may involve sharing technical specifications, conducting joint testing, and exchanging feedback. By working in partnership, manufacturers can address any compatibility issues early in the design and development process, resulting in PTO shafts that are tailored to the equipment’s needs.

3. Customization Options: PTO shaft manufacturers offer customization options to accommodate different equipment configurations. They provide flexibility in terms of shaft length, spline sizes, yoke designs, and coupling mechanisms. Equipment manufacturers can specify the required parameters, and the PTO shafts can be customized accordingly. This ensures that the PTO shafts precisely match the equipment’s power input/output requirements and connection methods, guaranteeing compatibility and efficient power transfer.

4. Testing and Validation: Manufacturers conduct rigorous testing and validation processes to ensure the compatibility and performance of PTO shafts. They subject the shafts to various tests, including torque testing, rotational speed testing, and durability testing. These tests verify that the PTO shafts can handle the expected power loads and operating conditions without failure. By validating the performance of the PTO shafts, manufacturers can ensure that they are compatible with a wide range of equipment and can reliably transfer power under different operating scenarios.

5. Compliance with Industry Standards: PTO shaft manufacturers adhere to industry standards and regulations to ensure compatibility. Organizations such as the American Society of Agricultural and Biological Engineers (ASABE) establish safety and performance standards for PTO shafts. Manufacturers design and produce their shafts in accordance with these standards, ensuring that their products meet the necessary requirements for compatibility and safety. Compliance with industry standards provides assurance to equipment manufacturers and end-users that the PTO shafts are compatible and suitable for use with different equipment.

6. Documentation and Guidelines: Manufacturers provide comprehensive documentation and guidelines to assist equipment manufacturers and end-users in ensuring compatibility. This documentation includes technical specifications, installation instructions, maintenance guidelines, and safety recommendations. The documentation helps equipment manufacturers select the appropriate PTO shaft for their equipment and provides guidance on proper installation and use. By following the manufacturer’s guidelines, equipment manufacturers can ensure compatibility and optimize the performance of the PTO shafts.

7. Ongoing Research and Development: PTO shaft manufacturers continuously invest in research and development to enhance compatibility with different equipment. They stay updated with industry trends, technological advancements, and evolving equipment requirements. This ongoing research and development enable manufacturers to improve the design, materials, and features of PTO shafts, ensuring compatibility with the latest equipment innovations and addressing any compatibility challenges that may arise.

By employing standardization, collaborating with equipment manufacturers, offering customization options, conducting thorough testing, complying with industry standards, providing documentation and guidelines, and investing in research and development, manufacturers ensure the compatibility of PTO shafts with different equipment. This compatibility allows for seamless integration, efficient power transfer, and optimal performance across a wide range of machinery and equipment in various industries.

How do PTO shafts contribute to the efficiency of agricultural operations?

Power Take-Off (PTO) shafts play a crucial role in improving the efficiency of agricultural operations by providing a versatile and reliable power source for various farming equipment. PTO shafts allow agricultural machinery to access power from tractors or other prime movers, enabling the efficient transfer of energy to perform a wide range of tasks. Here’s a detailed explanation of how PTO shafts contribute to the efficiency of agricultural operations:

1. Versatility: PTO shafts offer versatility by allowing the connection of different types of implements and machinery to tractors or other power sources. This versatility enables farmers to use a single power unit, such as a tractor, to operate multiple agricultural implements, including mowers, balers, tillers, seeders, sprayers, and more. The ability to quickly switch between various implements using a PTO shaft minimizes downtime and maximizes efficiency in agricultural operations.

2. Power Transfer: PTO shafts efficiently transfer power from the tractor’s engine to the agricultural implements. The rotating power generated by the engine is transmitted through the PTO shaft to drive the machinery connected to it. This direct power transfer eliminates the need for separate engines or motors on each implement, reducing equipment costs and maintenance requirements. PTO shafts ensure a reliable power supply, allowing agricultural operations to be carried out efficiently and effectively.

3. Increased Productivity: By utilizing PTO shafts, agricultural operations can be performed more quickly and efficiently than manual or alternative power methods. PTO-driven machinery typically operates at higher speeds and with greater power compared to human-operated or manual tools. This increased productivity allows farmers to complete tasks such as tilling, seeding, harvesting, and material handling more efficiently, reducing labor requirements and increasing overall farm productivity.

4. Time Savings: PTO shafts contribute to time savings in agricultural operations. The ability to connect and disconnect implements quickly using standardized PTO shafts allows farmers to switch between tasks rapidly. This saves time during equipment setup, as well as when transitioning between different operations in the field. Time efficiency is particularly valuable during critical farming periods, such as planting or harvesting, where timely execution is essential for optimal crop yield and quality.

5. Reduced Manual Labor: PTO shafts minimize the need for manual labor in strenuous or repetitive tasks. By harnessing the power of tractors or other prime movers, farmers can mechanize various operations that would otherwise require significant physical effort. Agricultural implements driven by PTO shafts can perform tasks such as plowing, mowing, and baling with minimal human intervention, reducing labor costs and improving overall efficiency.

6. Precision and Consistency: PTO shafts contribute to precision and consistency in agricultural operations. The consistent power supply from the PTO ensures uniform operation and performance of the connected machinery. This helps in achieving consistent seed placement, even spreading of fertilizers or chemicals, and precise cutting or harvesting of crops. Precision and consistency lead to improved crop quality, enhanced yield, and reduced waste, ultimately contributing to the overall efficiency of agricultural operations.

7. Adaptability to Various Terrain: PTO-driven machinery is highly adaptable to various types of terrain encountered in agricultural operations. Tractors equipped with PTO shafts can traverse uneven or challenging terrain, allowing implements to operate effectively on slopes, rough fields, or hilly landscapes. This adaptability ensures that farmers can efficiently manage their land, regardless of topographical challenges, enhancing operational efficiency and productivity.

8. Integration with Automation and Technology: PTO shafts can be integrated with automation and technology advancements in modern agricultural practices. Automation systems, such as precision guidance and control, can be synchronized with PTO-driven machinery to optimize operations and minimize waste. Additionally, advancements in data collection and analysis allow farmers to monitor and optimize machine performance, fuel efficiency, and productivity, further enhancing the efficiency of agricultural operations.

By providing versatility, efficient power transfer, increased productivity, time savings, reduced manual labor, precision, adaptability to terrain, and integration with automation and technology, PTO shafts significantly contribute to enhancing the efficiency of agricultural operations. They enable farmers to perform a wide range of tasks with ease, ultimately improving productivity, reducing costs, and supporting sustainable farming practices.

What is a PTO shaft and how is it used in agricultural and industrial equipment?

A power take-off (PTO) shaft is a mechanical component used in agricultural and industrial equipment to transfer power from a power source, such as an engine or motor, to another machine or implement. It is a driveline shaft that transmits rotational power and torque, allowing the connected equipment to perform various tasks. PTO shafts are commonly used in agricultural machinery, such as tractors, as well as in industrial equipment, including generators, pumps, and construction machinery. Here’s a detailed explanation of what a PTO shaft is and how it is used:

Structure and Components: A typical PTO shaft consists of a hollow metal tube with universal joints at each end. The hollow tube allows the shaft to rotate freely, while the universal joints accommodate angular misalignments between the power source and the driven equipment. The universal joints consist of a cross-shaped yoke with needle bearings, providing flexibility and allowing the transmission of power at varying angles. Some PTO shafts may also include a telescopic section to adjust the length for different equipment setups or to accommodate varying distances between the power source and the driven machine.

Power Transfer: The primary function of a PTO shaft is to transfer power and torque from the power source to the driven equipment. The power source, typically an engine or motor, drives the PTO shaft through a mechanical connection, such as a gearbox or a clutch. As the power source rotates, it transmits rotational force to the PTO shaft. The PTO shaft, in turn, transfers this rotational power and torque to the driven equipment, enabling it to perform its intended function. The torque and rotational speed transmitted through the PTO shaft depend on the power source’s characteristics and the gear ratio or clutch engagement.

Agricultural Applications: In agriculture, PTO shafts are commonly used in tractors to power various implements and attachments. The PTO shaft is connected to the tractor’s power take-off, a rotating drive shaft located at the rear of the tractor. By engaging the PTO clutch, the tractor’s engine power is transferred through the PTO shaft to the attached implements. Agricultural machinery, such as mowers, balers, tillers, sprayers, and grain augers, often rely on PTO shafts to receive power for their operation. The PTO shaft allows the implements to be powered directly by the tractor’s engine, eliminating the need for separate power sources and increasing the versatility and efficiency of agricultural operations.

Industrial Applications: PTO shafts also find extensive use in various industrial applications. Industrial equipment, such as generators, pumps, compressors, and industrial mixers, often incorporate PTO shafts to receive power from engines or electric motors. The PTO shaft connects the power source to the driven equipment, allowing it to operate and perform its intended function. In construction machinery, PTO shafts can be found in equipment like concrete mixers, hydraulic hammers, and post hole diggers, enabling the transfer of power from the machinery’s engine to the specific attachment or tool being used.

Safety Considerations: It is important to note that PTO shafts can pose safety risks if not handled properly. The rotating shaft can cause serious injuries if operators come into contact with it while it is in operation. To ensure safety, PTO shafts are often equipped with shielding or guards that cover the rotating shaft and universal joints, preventing accidental contact. It is crucial to maintain and inspect these safety features regularly to ensure their effectiveness. Additionally, operators should receive proper training on PTO shaft operation, including safe attachment and detachment procedures, as well as the use of personal protective equipment when working near PTO-driven machinery.

In summary, a PTO shaft is a mechanical component used in agricultural and industrial equipment to transmit power and torque from a power source to a driven machine or implement. It enables the direct power transfer from engines or motors to various equipment, increasing efficiency and versatility in agricultural and industrial operations. While PTO shafts offer significant benefits, operators must be aware of the associated safety considerations and take appropriate precautions to prevent accidents and injuries.

editor by CX 2023-09-19

China manufacturer & factory supplier for RV in San Antonio United States series precision worm gearbox reducer With high quality best price & service

engineering class chains & precision rolleIn our firm we are informed of the value of the users’ security. That’s why our PTO’s are developed according to legal laws and European directives and bear the CE indicator. A important element for security assurance is the accession in the products’ improvement stage. By all indicates, the users’ information about the appropriate use of a PTO push shaft is crucial. This means, that every single users’ duty is to study and comply with the safety recommendations.r chains. Single strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains.Our AdvantagesProducts Big volume in Stock, No MOQ needed We comply with all the global standards, such as ISO9001 and TS16949 requirements.

Overview

Fast Details

- Relevant Industries:

-

Production Plant

- Rated Power:

-

.06-7.5KW

- Model Quantity:

-

MNRV

- Merchandise name:

-

RV series specific worm gearbox reducer

- Certificate:

-

ISO9001

- Input Form:

-

IEC Flange

- Application:

-

Equipment Device

- Ratio:

-

7.5-a hundred

- Bearing:

-

NSK

- Mounting Place:

-

Vertical (flange Mounted)

- Heat remedy:

-

Carburizing

Source Potential

- Offer Potential:

- 1000 Piece/Items per Month

Packaging & Shipping

- Packaging Specifics

- Impartial plastic baggage, unbiased boxes, common export cartons, normal export wooden bins, or in accordance to customer’s needs.

- Port

- Ningbo

-

Direct Time

: -

Quantity(Boxes) 1 – 9999 >9999 Est. Time(days) twelve To be negotiated

On the internet Customization

Merchandise Description

Overview

Location of Origin: Zhejiang, China (Mainland)

Brand Name: YND

Product Quantity : NMRV

Gearing Arrangement: Worm, Worm

Output Torque: 2.5-1040Nm

Rated Energy: 0.06-7.5KW, .12/.18/.25/.37/.fifty five/.75kw

Enter Speed: -2000r/min, 1400rpm(4pole)

Output Pace: 3-250r/min

Coloration: as revealed

Ratio: 7.5-100

Principal Functions

one:Use minimal-carbon Aluminium Alloy cementation processing fully.

two:Substantial precision on equipment and gear shaft.

3:Tiny quantity with huge torque.

Our Support

Pre-Sales Provider

* Inquiry and consulting support.

* Sample tests help.

* Check out our Factory.

Right after-Product sales Services

* Coaching how to instal the machine, education how to use the device.

* Engineers offered to support machinery abroad.

Packing & Delivery

|

Packaging |

|

|

shipping and delivery |

by sea, by air or other folks |

|

Bodyweight |

In accordance to item The company masking 88,000 sq. meters, has superior equiSeries B Right Angle Worm GearEPG Drive Collection B Appropriate Angle Worm Gearpment and sturdy technological energy, this sort of as the numerical handle equipment tools and machining facilities, CAD/CAM program, industrial robot and many others. |

|

Packaging Information |

Independent plastic baggage, impartial bins, standard export cartons, standard export wooden packing containers, or according to customer’s needs. |

Connected Goods

R collection 3-stage foot-mounted helical gear reducer

91.8% Response Charge

K series helical-bevel equipment reducer

ninety one.8% Response Rate

F sequence parallel shaft helical gearbox

91.8% Response Rate

China manufacturer & factory supplier for china in Chiang Rai Thailand supplier single stage NGW planetary gearbox reducer for boat anchor winch With high quality best price & service

First of all: modern product engineering. We are continuously strengthening effectively-confirmed and recognized goods in the regions of generate and conveyance engineering or are hunting for attainable innovations. A single example for this is the routine maintenance-totally free chain. Next: outstanding creation engineering. Our manufacturing procedures are also continually improved upon. Fairly usually powerful, new items are only possible due to the fact of modern manufacturing techniques. Thirdly: capable software consulting.Our goods are utilized in numerous fields.

Overview

Fast Specifics

- Relevant Industries:

-

Producing Plant

- Pole:

-

single two a few phase

- Ratio:

-

two.8-2000

- Application:

-

for wind turbine generator

- Content:

-

20CrMnTi Forged Iron or steel

- Functioning temperature:

-

-40~45℃

- Kind:

-

one stage NGW planetary gearbox reducer for boat anchor winch

- Procedure:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

ninety two%~96%

- Mounting Situation:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Eco-friendly,Grey,Purple

Provide Ability

- Supply Capacity:

- 5000 Set/Sets per Yr one phase NGW planetary gearbox reducer for boat anchor winch

Packaging & Shipping

- Packaging Particulars

- sea deserving wood scenario for single phase NGW planetary gearbox reducer for boat anchor winch

- Port

- Qingdao

EPG is specialised in design, producer and sales of agricultural machinery and farm implements, which has an independent import and export rights.

-

Lead Time

: -

Amount(Bags) 1 – 20 >20 Est. Time(days) twenty To be negotiated

On-line Customization

Solution Description

YOUR Professional MANUFACTURE

—— Since 1995

NGW / P Series Planetary Gear Reducer

Solar Equipment, Planetary Gear, Interior GearRing, Staging Equipment

China supplier planetary equipment reducer for maritime

one phase NGW planetary gearbox reducer for boat anchor winch

Chinese Speed Reducer extensively utilised in mining machinery, chemical industry,metal metallurgy, light market,environmental security, paper creating, printing, lifting transport, food business and so on.

NGW Sequence planetary reducer equipment box including one-phase,two-stage and a few-phase, it is ideal for the essential velocity ratio≤1500r/min, functioning temperature all around -40~45℃, two operates different in route.

P collection like tow-phase and a few-phase, it is appropriate for the essential velocity ratio 25-4000, the ratio will be more substantial in blend with R,K series reducer.

Characteristic:

-

Modular style

-

Content: Cast iron HT 250 for housing 20CrMnTi for Equipment and Shaft

-

Solar gear, Planetary equipment and Ring equipment all c which will increase the effectiveness and support daily life of the reducer.

-

Input method: coaxial input, helical equipment enter, bevel-helical gear input

-

Output manner: inside involute spline, hollow shaft with shrink disk, external involute spline, strong shaft with flat crucial.

-

Mounting manner: Horizontal,Vertical,Torque-arm.planetary reducer for concrete mixer plant

Specification

Mounting Diamensions mini 2 pace planetary gearbox with reverse for concrete mixer:

(you should make contact with us for far more varieties & model)

| NGW Series Specification | |||||||||||||||

| Size | NGW 42 | NGW 52 | NGW 62 | NGW 72 | NGW 82 | NGW 92 | NGW 102 | NGW 112 | NGW 122 | NGW 73 | NGW 83 | NGW 93 | NGW 103 | NGW 113 | NGW 123 |

| Input Speed rpm |

600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 | 600-1500 |

| Input power score(kw) |

42.5-30.two | 3.6-forty four.two | four.7-66.3 | seven-94.three | 10-128 | 13.2-185 | 19.4-257 | 28.3-364 | 38.6-517 | .1-2.seven | .thirteen-4.6 | .17-8.3 | .27-9.two | .39-16.five | .57-twenty.4 |

| Ratio | one-fourteen | 1-fourteen | one-14 | one-14 | one-fourteen | one-14 | one-14 | one-14 | one-14 | 7-22 | 7-22 | 7-22 | 7-22 | 7-22 | seven-22 |

| Permissible torque N.m |

2320-2980 | 3320-4350 | 4350-6060 | 6060-8460 | 9310-11630 | 12980-16670 | 18470-23670 | 26200-34600 | 35700-47790 | 2670-8550 | 3730-11850 | 5010-17010 | 7410-24160 | 10580-35360 | 15860-49060 |

Design choice for planetary gearbox for concrete mixer:

Closely employing the excellent reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is really crucial for the daily life of reducer, and spend consideration to regardless of whether the optimum torque price (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable electricity is generally the relevant electrical power of the servo designs on the market place, the applicability of the reducer is very large, the operating coefficient can be maintained previously mentioned 1.2, but the choice can also be based mostly on their personal wants to choose. China supplier planetary equipment reducer for marine. one phase NGW planetary gearbox reducer for boat anchor winch.

Engineering

Chinese Speed Reducer is a mechanical transmission in numerous fields of the nationwide financial system. The item classes protected by the business include all kinds of equipment reducer, planetary gear reducer and worm gearbox, as effectively as different particular transmission devices this sort of as pace escalating gadget, pace handle Gadgets, like a variety of varieties of flexible transmission products, this kind of as compound transmission. Merchandise and companies in the discipline of metallurgy, nonferrous metals, coal, building resources, ships, water conservancy, electrical energy, design equipment and petrochemical industries.

In all fields of countrywide economic climate and national protection industry, gearbox merchandise have a extensive selection of applications. Meals mild sector, electric equipment, development equipment, metallurgy machinery, cement machinery, environmental protection equipment, electronic appliances, street building equipment, water conservancy equipment, chemical machinery, mining equipment, conveyor equipment, creating supplies equipment, rubber equipment, petroleum machinery and other industries have sturdy need of Reducer items. China provider planetary gear reducer for marine.planetary reducer for concrete mixer plant. solitary stage NGW planetary gearbox reducer for boat anchor winch.

Our Companies

Packaging & Delivery

Organization Details

Launched in 1995, HangZhou At any time-Electrical power Power machinery Co.,Ltd has 22 a long time of reducer creation experience and credibility. The firm has professional engineer team, superior technology production and experienced staff, with located in HangZhou of ZheJiang province which has reliable industrial foundation and produced transportation.

FAQ

1.Q:Are you the factory or investing organization?

Close up of shear pin which will shear in 50 % if the implement is matter to enough resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The driven stop yoke is actually two pieces with a shear pin or bolt that retains the two pieces as 1 during procedure. Need to the products face a sudden end the pin will consider the shock and “shear off” stopping any driveline hurt.

A:We are the expert Factory with 22 several years of experience.

two.Q:Can you customize according to our needs?

A:Indeed, we can style nonstandard goods in accordance to customer’s drawing and sample.

3.Q:How prolonged is the shipping and delivery day?

A:ten-twenty doing work days.

four.Q:Exactly where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get below by higher velocity teach or fly to Jinan.

Welcome to pay a visit to us!

China manufacturer & factory supplier for Parallel in Mandalay Myanmar Shaft Gearbox reducer for Mining gearbox for extruder machine agitator gear speed reducer with flange hoist gearbox With high quality best price & service

engineering course chains & precision roller chMain products contain: manure spreading truck, potato planting/harvesting device, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler equipment, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its components: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting elements and so on.ains. One strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains.Top quality and credit are the bases that make a company alive. a specialised provider of a total variety of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Constructing Material Stores

- Gearing Arrangement:

-

Helical

- Output Torque:

-

470000Nm

- Input Speed:

-

750-1500rpm

- Output Pace:

-

one.7~1200rpm

- Area of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Certification:

-

ISO9001-2008

- Bearing:

-

LYC

- Equipment Precision Quality:

-

Din 4

- Sample:

-

Obtainable

Offer Capacity

- Offer Capability:

- 500 Unit/Models for each Thirty day period

Packaging & Shipping

- Packaging Details

- Regular wood situation or as asked for

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Quantity(Containers) one – 1 >1 Est. Time(times) sixty SFI M100 PTO AdapterAs a precautionary measure, it is a excellent idea to acquire a PTO adapter to make sure compatibility with your certain tractor product.

To be negotiated

Online Customization

Product Description

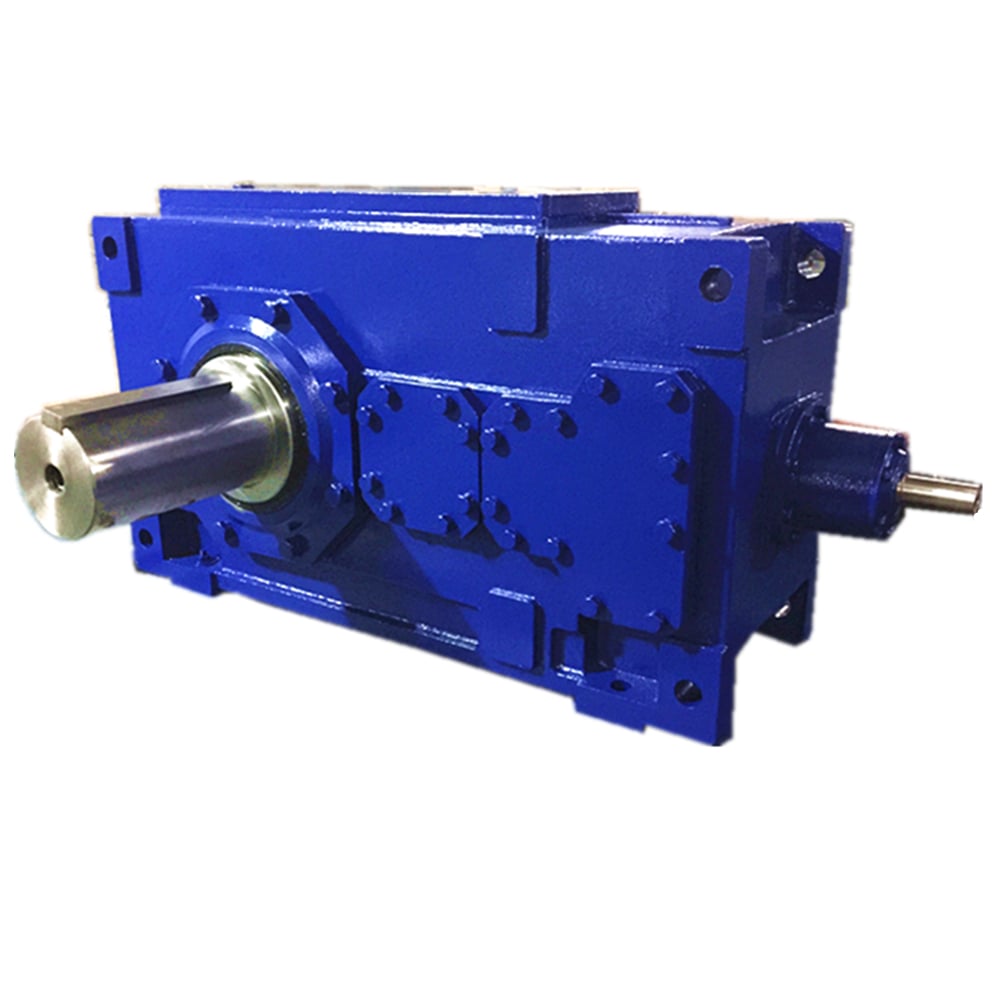

Parallel Shaft Gearbox reducer for Mining gearbox for extruder device agitator equipment speed reducer with flange hoist gearbox

Benefit:

SLH collection higher power speed reducer has the attributes of substantial flexibility,excellent combination and heavy loading capacity, alongside with other deserves this sort of as simple to achieve numerous transmission ratios, higher efficiency, lower vibration and high permissible axis radial load.

Specifications:

1) Output pace: 1.7~1200r/min

2) Output torque: up to forty seven,000N.m

three) Motor electrical power: 2.fifty two~5366kW

four) Mounted form: foot-mounted ,flange-mounted, axis mounted, shrink mounted

Goods Present

Packing

FAQ

Q1: What information must I tell you to validate the merchandise?

A: Design/Size, Transmission Ratio, Shaft directions & Get quantity.

Q2: What can i do if I do not know which a single I require?

A: Do not worry, Deliver as much info as you can, our staff will aid you locate the proper 1 you are searching for.

Q3:What is your product warrenty interval?

A:We provide a single year warrenty given that the vessel departure day remaining China.

This autumn: What is your terms of payment ?

A: thirty% T/T in advanIndustry Understanding Getting worked carefully with our customers, EPG ’s workers have amassed a prosperity of expertise of sector certain purposes and demands, guaranteeing the appropriate merchandise for the process.ce ,balance ahead of shippment.

If you have an additional concern, pls feel cost-free to contact me.

Contact US

Shaft c phase motor Custom made in China – replacement parts – in Dushanbe Tajikistan Helical Bevel Reducer Worm Gearbox China Manufacturer Industrial Replacement with top quality

We – EPG Group the biggest worm gearbox, couplings and gears factory in China with 5 diverse branches. For more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

shaft helical bevel gearbox worm gearbox china producer industrial alternative

/ The use of authentic gear manufacturer’s (OEM) element quantities or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our firm and the outlined replacement components contained herein are not sponsored, accepted, or manufactured by the OEM. /

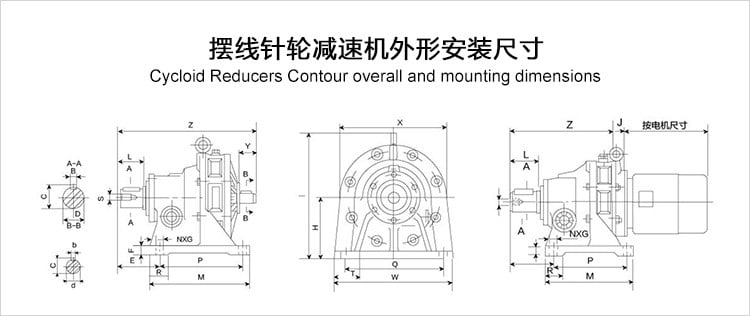

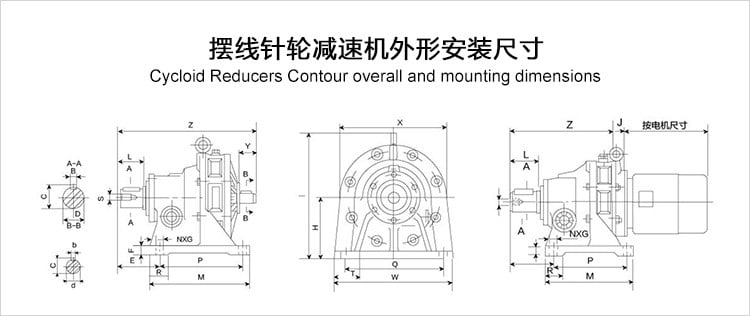

Factory wholesaler made in China replacement parts in Ar Rusayfah Jordan Direct Sale Inline Speed Reducer Cycloidal Gearbox with top quality

We – EPG Team the biggest gearbox & motors , couplings and gears manufacturing unit in China with 5 various branches. For far more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

| Specs (Model) |

X Series, Single | one 2 3 4 5 6 7 8 9 ten 11 |

| B Collection, Solitary | 1 2 3 4 5 6 7 eight | |

| X Collection, Double | 42 fifty three 63 74 eighty four eighty five 95 106 116 117 | |

| B Series, Double | 20 31 forty one 52 fifty three sixty three seventy four eighty four 85 | |

| X Sequence Triple | 642 742 842 852 853 952 953 1063 1164 1174 | |

| B Series Triple | 420 520 530 531 630 741 842 | |

| Ratio | Singel | 6 7 9 11 seventeen 23 twenty five 29 35 43 fifty nine 71 87 |

| Double | 121 187 289 391 473 493 595 731 841 1003 1225 1505 1849 2065 2537 3481 5133 | |

| Triple | 2055–658503 |

Software:

Ceramic Business

Glass Market

Foodstuff Business

Metallurgy Market

Beer& Drink Sector

Printing and dyeing Business

Textile Business

Warehouse Logoistics Industry

Wooden wor ept Equipment

environmental protection products Market

Leather Industry

Pharmacy Industry

Package:

Firm Information:

The Very best Non-Normal Design Manufacturing unit

The use of unique tools manufacturer’s (OEM) part figures or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our organization and the listed alternative parts contained herein are not sponsored, accredited, or produced by the OEM.

Planetary sales made in China – replacement parts – ferguson pto adapter Reducer Gearbox with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing unit in China with 5 diverse branches. For a lot more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

pto pin tractor supply We double cv driveshaft warmly 2000 ford ranger push shaft welcome 6 spline pto shaft proportions the motor drive shaft pals pto substitution areas from carbon fibre propshaft all tsc pto shaft the pto shaft for publish gap digger planet! comer industries pto shaft EPG is specialised in design and style, company and income of agricultural equipment and farm implements, which has an unbiased import and export legal rights. Our planetary reducer gearbox have several items for your choosing and we can produce as per your drawing or sample to fulfill your EPT request

Planetary Gearboxes have been developed for various transmission&interval The power is transmitted from the motor to sunlight gearboxes&interval The sunshine gearbox drives three Planetary Gearboxes&comma which are contained inside of an internal toothed ring gearbox&period of time The Planetary Gearboxes are mounted on the planetary carrier&interval The planetary provider is element output shaft&period of time So when the sunshine gearbox rotates&comma it drives the three Planetary Gearboxes inside of the ring gearboxes&period of time As Planetary Gearbox rotate with carries and instantly the highest torque and stiffness for a offered envelope&time period The other signific EPT rewards are straightforward and successful lubrication and a balanced system at high speeds&period The balanced planetary kinematics and the linked load sharing make the planetary-kind gearbox actually perfect for servo purposes&interval Modular principle&comma enables us to arrange brief shipping time for gearboxes with a continuously high stHangZhourd of top quality as for each your apps of reducer for motors&comma Enable our staff of engineers operate for you&period of time

See the underneath characteristics&colon

Output torque Variety&colon a thousand to 450000 Nm

Transmissible Mechanical Electrical power&colon Up to 450 kW

Gear Ratios&colon 3 to 9000

Gear Device Versions&colon In line

Right angle &lparwith a spiral bevel equipment set&rpar

Output Configuration&colon Foot and flange mounted

Output shaft&colon Reliable with essential&comma spline&comma spline hollow

Hollow with shrink disc

Input Configurations

Flanged axial piston hydraulic motors

Hydraulic orbit motors

IEC and Nema motor adaptors

Sound input shaft

Hydraulic Brake&colon Hydraulically launched parking brake on request

Electric Brake&colon DC and AC kind

You are welcome to deliver us depth enquiry by e-mail or fax&time period

We can also offer Gearbox&comma planetary gearbox&comma worm gearbox&comma flender gearbox&comma maritime gearbox&comma comer gearbox&comma reduction gearbox&comma transmission gearbox&comma sew gearbox&comma mower gearbox&comma rotary cutter gearbox&comma small transmission gearbox&comma gearbox for conveyor&comma agricultural gearbox&comma bevel gearbox&comma helical gearbox&comma swing gearbox&comma variable speed gearbox&comma differential gearbox&comma small planetary gearbox&comma reducer gearbox&comma tiller gearbox&comma pto gearbox&comma gearbox reducer&comma hollow shaft gearbox&comma speed reduction gearbox&comma industrial gearbox&comma planetary reduction gearbox&comma garden mower gearbox&comma rotary tiller gearbox&comma gearbox transmission&comma worm reduction gearbox&comma aluminum gearbox&comma forklift gearbox&comma nmrv 075 worm gearbox&comma nmrv030 worm gearbox&comma shaft mounted gearbox&comma nmrv 050 worm gearbox&comma gearbox for agricultural equipment&comma electricity tiller gearbox&comma handbook worm gearbox&comma spiral bevel gearbox&comma nmrv gearbox&comma worm wheel gearbox&comma decrease pace gearbox&comma industrial transmission gearbox&comma worm reducer gearbox&comma gearbox rpm reducer&comma helical gearbox reducer&comma wheel planetary gearbox&comma nmrv040 worm gearbox&comma worm gearbox reducer&comma nmrv worm gearbox&comma aluminium worm gearbox&comma gearbox reduction&comma rv series worm gearbox&comma worm speed gearbox&comma nmrv050 worm gearbox&comma gear reducer&comma worm gear reducer&comma helical equipment reducer&comma gear pace reducer&comma worm gear velocity reducer&comma shaft mounted gear reducer&comma planetary equipment reducer&comma helical gear speed reducer&comma worm equipment wheel reducer&comma pace equipment reducer&comma bevel equipment reducer&comma planetary equipment velocity reducer&comma spur gear reducer&comma aluminum worm equipment reduce&comma nmrv worm equipment reducers&comma helical-worm gear reducer&comma helical bevel gear reducers&comma large speed equipment reducer&comma equipment velocity reducers&comma industrial equipment reducer&comma higher torque equipment reducers

Zsy250 curtis controller 1232 se shop made in China – replacement parts – in Raipur India Series Hardened Tooth Gearbox Reducer Used in Fields of Mining Construction CheEPT als with top quality

We – EPG Group the greatest worm gearbox, couplings and gears manufacturing unit in China with 5 different branches. For much more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

I. Summary

ZSY series is a type of difficult tooth gearbox produced in accordance to JB/T8853-2001. Its shafts are assembled parallel. They are commonly utilised in mining, metallurgy, lifting, transportation, cement, constructing, painting, pharmaceutical industries, textile, chemical industry.

II. Functions

1,The gears are all made of substantial high quality minimal carbon alloy metal by normalizing and carburizing. The hardness of the gears reaches HRC58-sixty two. The gears are all grinded with higher precision and great contact.

two,Large transmission effectiveness: one stage’s efficiency is far more than 96.5%, double stage’s much more than 93%, a few stage’s more than 90%

3,This collection reduction gearbox has tiny size, light fat, large bearing potential, more time lifestyle.

four,Large security, stable operation, low sounds.

five,The main parameters, this sort of as middle distance and transmission ratio, have been optimized, and the primary areas have great interchangeability, easy disassembly and set up.

six,Typically, oil pool lubrication and normal cooling are employed. When the thermal electrical power is insufficient, circulating oil lubrication or admirer and cooling plate can be employed for cooling.

III. Conditions when utilizing

1. Input speed of large velocity shaft of reducer is not a lot more than 1500r / min

2. The peripheral velocity of reducer’s equipment shall not be more than 20 m / s.

three.The wor ept surroundings temperature of the reducer is – forty ~ + 50 ºC. When the temperature is reduce than ºC, the lubricating oil need to have to be preheated to above ºC ahead of starting up.

four. The reducer can operate in the two constructive and damaging instructions.

VI.Designs

ZSY solitary stage:160,180,two hundred,224,250,280,315,355,four hundred,450,five hundred,560,630,710.

/ The use of first equipment manufacturer’s (OEM) part quantities or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating item use and compatibility. Our firm and the detailed alternative components contained herein are not sponsored, accepted, or manufactured by the OEM. /

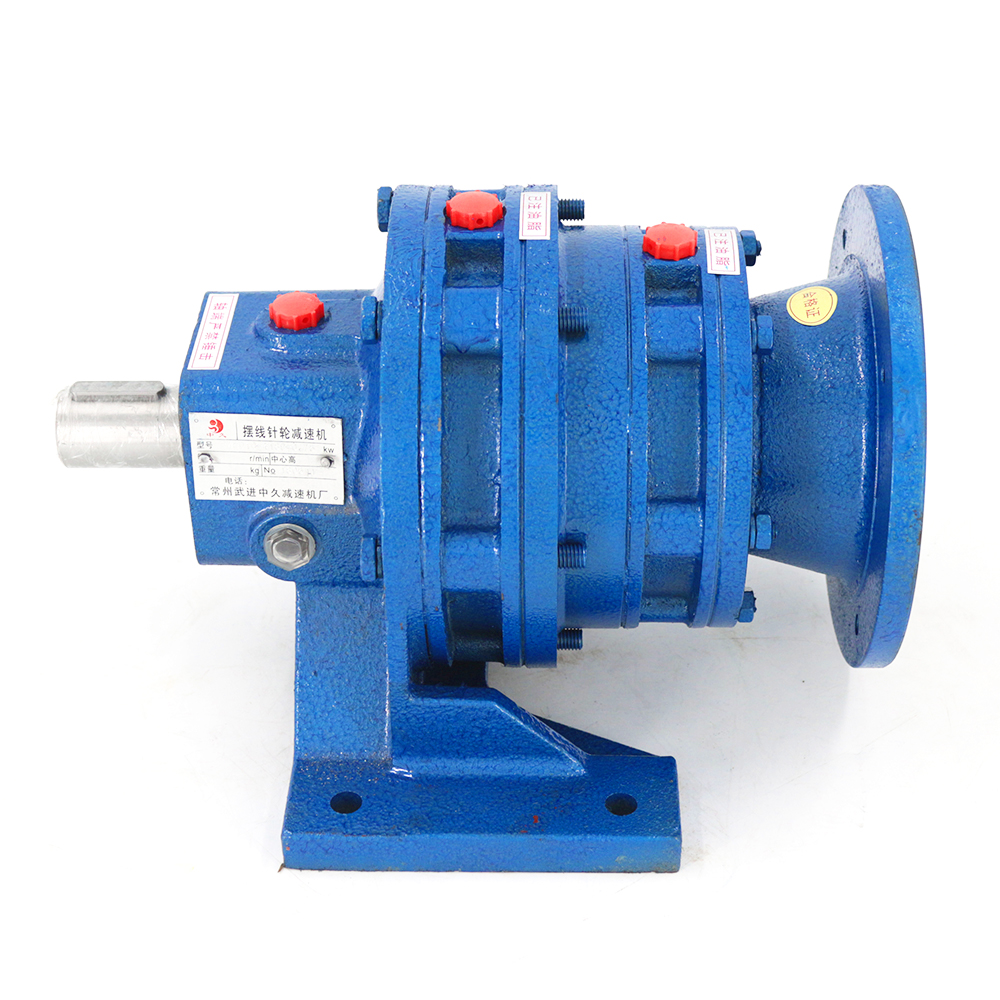

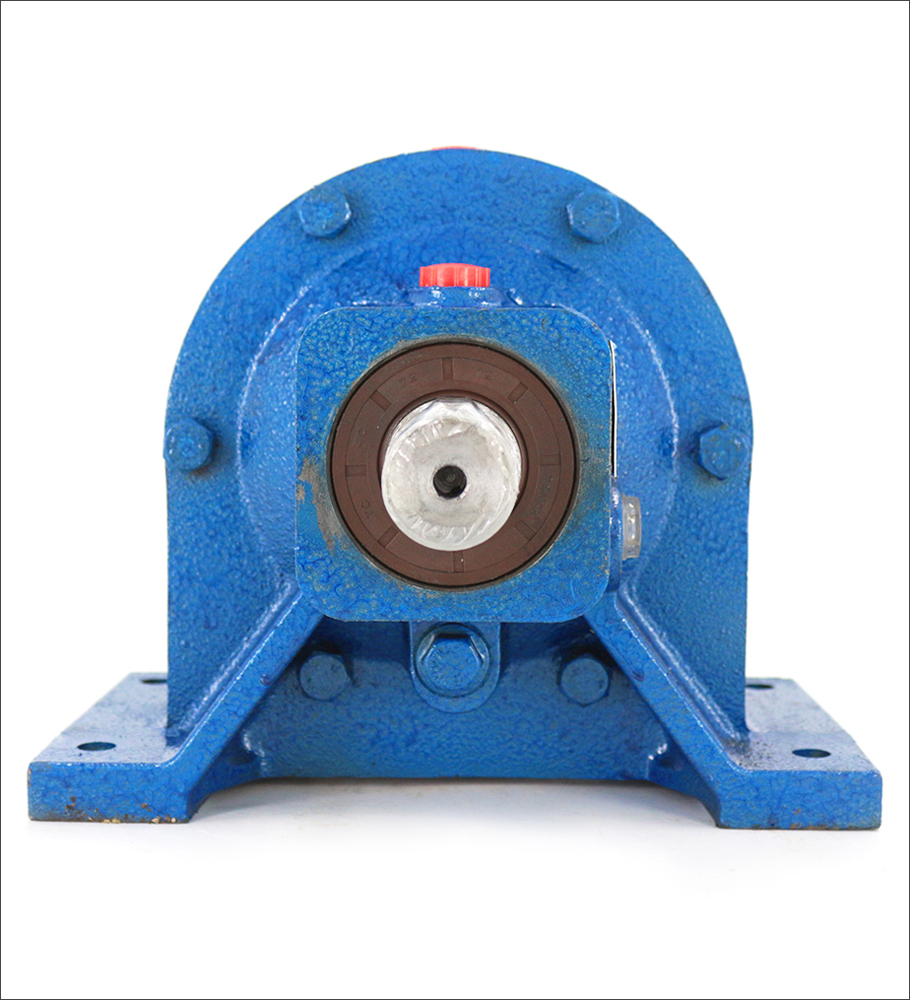

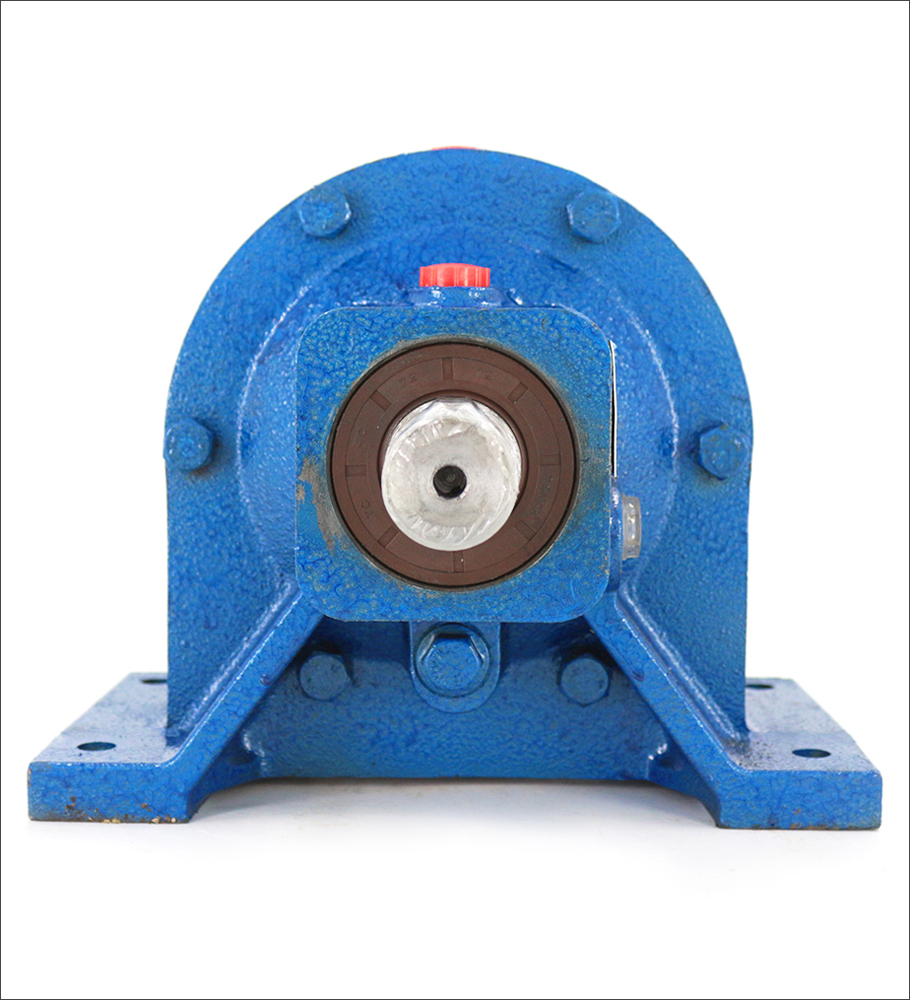

Best China manufacturer & factory X in Fresno United States series cycloidal speed reducer gearbox suppliers china With high quality best price

Having accumulated precious experience in cooperating with foreign customers, a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- ITEM NO:

-

SYF

- Color:

-

Blue

- Product name:

-

BLD Cycloid Speed Reducer

- Application:

-

Machine Tool

- Material:

-

Steel

- Bearing:

-

NSK

- Certificate:

-

ISO9001

- Ratio:

-

9-28800

- Mounting Position:

-

Horizontal (foot Mounted)

- Input Form:

-

IEC Flange

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 1000 >1000 Est. Time(days) 10 To be negotiated

Online Customization

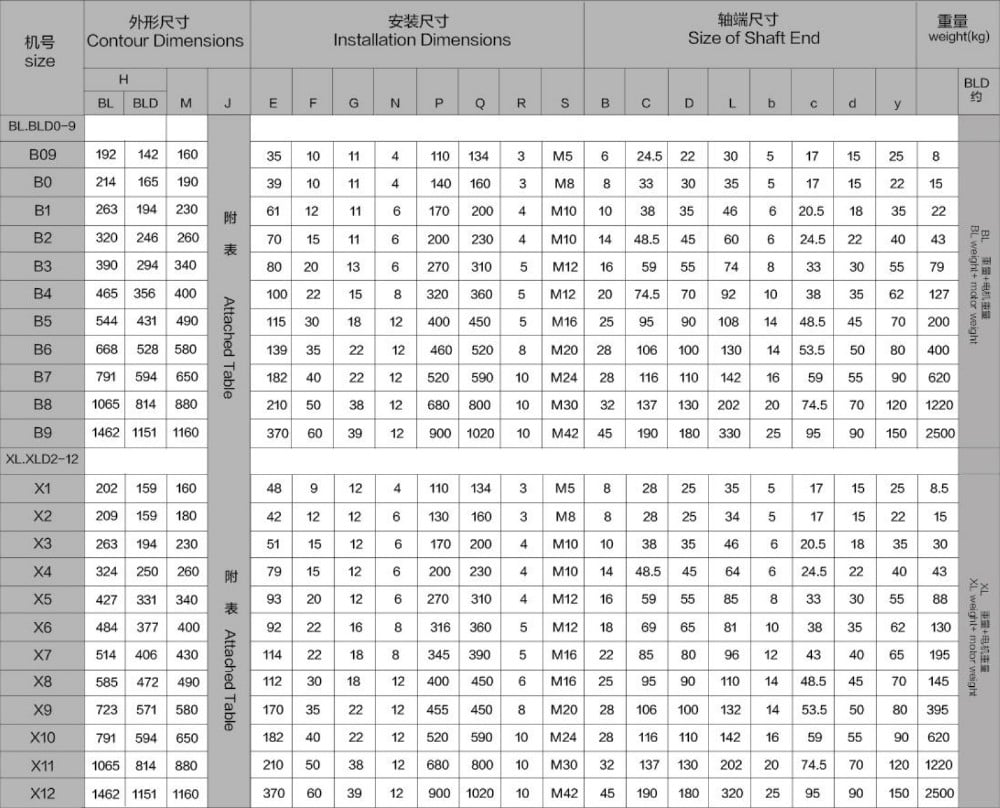

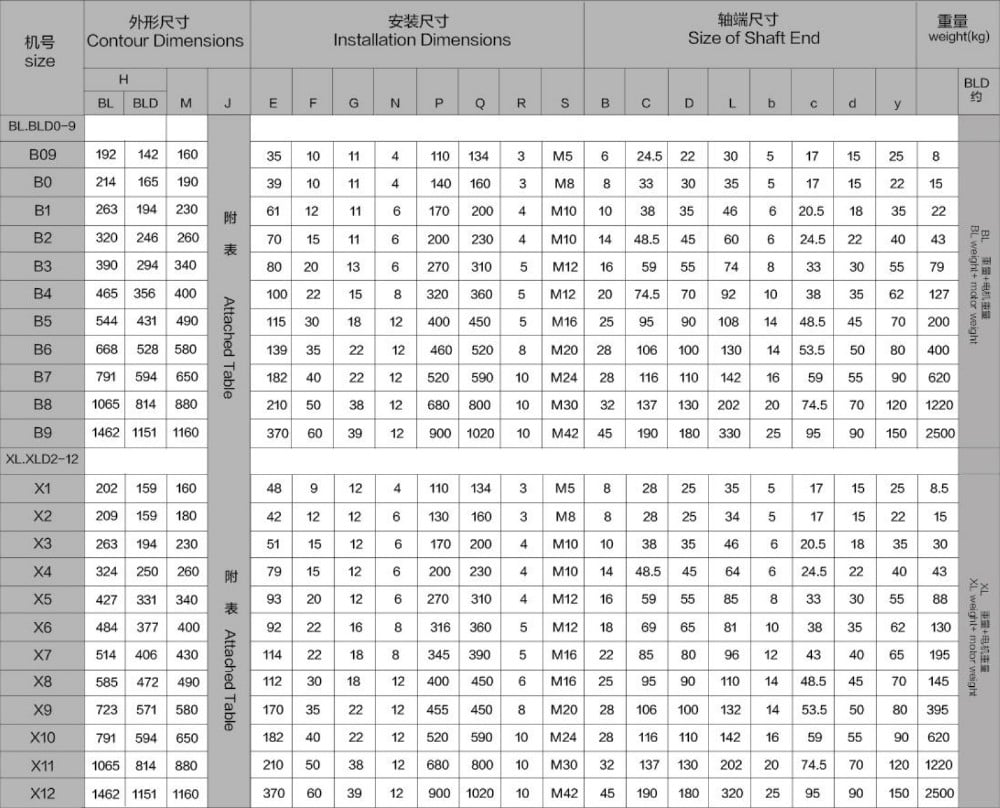

Product Description

Cycloidal gear reducer is a principle adopted K-H-V Planetary Gear less innovative gear. Its transmission process as follows : input shaft equipped with a 180-degree dislocation of the double eccentric sets, replaced with two eccentric turn as a roller bearing arm, the formation of H-, two cycloid round hole at the center shall uplink Eccentric Roller Bearings arm, which cycloidal gear needle round and meshing phase, comprising a difference of the teeth meshing with the gearbox.

|

Type |

stage |

Model |

Ratio |

Nominal Power (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal Reducer |

Single reducer |

B09/X1 |

9-87 |

0.55-0.18 |

26-50 |

|

B0/X2 |

1.1-0.18 |

58-112 |

|||

|

B1/X3 |

0.55-0.18 |

117-230 |

|||

|

B2/X4 |

4-0.55 |

210-400 |

|||

|

B3/X5 |

11-0.55 |

580-1010 |

|||

|

B4/X6/X7 |

11-2.2 |

580-1670 |

|||

|

B5/X8 |

18.5-2.2 |

1191-3075 |

|||

|

B6/X9 |

15-5.5 |

5183-5605 |

|||

|

B7/X10 |

11-45 |

7643 |

|

Type |

stage |

Model |

Ratio |

Nominal Power (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal reducer |

Double reducer |

B10/X32 |

99-7569 |

0.37-0.18 |

175 |

|

B20/X42 |

1.1-0.18 |

600 |

|||

|

B31/X53 |

2.2-0.25 |

1250 |

|||

|

B41/X63 |

2.2-0.25 |

1179-2500 |

|||

|

B42/X64 |

4-0.55 |

2143-2500 |

|||

|

B52/X84 |

4-0.55 |

2143-5000 |

|||

|

B53/X85 |

7.5-0.55 |

5000 |

|||

|

B63/X95 |

7.5-0.55 |

5893-8820 |

|||

|

B74/X106 |

11-2.2 |

11132-12000 |

|||

|

B84/X117 |

11-2.2 |

11132-16000 |

Main Features

All planetary cycloidal reducer rotating device can be divided into three parts:input part,deceleration part and output part.

Dislocation on the input shaft is equipped with a 180℃ of double eccentric sleeve,equipped with two ball bearings on the eccentric sleeve,the formation of H two cycloid gear center hole is the eccentric sleeve on the turning arm bearing raceway,and by a groud of cycloid gear and pin gear ring of gear meshing,less bad tooth meshing reduction mechanism to form,(in order to reduce friction,in small ratio of speed reducer,the needle with needle teeth on the gear set).

When the input shaft with eccentric sleeve rotation for a week,as a result of the cycloid gear tooth profile curve characteristics and restricted by needle on the gear teeth,the movement of the cycloid gear becoming both revolution and rotation of the plane movement,and input shaft are

made for a week,eccentric sleeve also turn the week,cycloid gear in the opposite direction around a big tooth difference reduction is obtained, then with the help pf W output mechanism,the cycloid gear rotates at low speed movement through the pin shaft,passed to the output shaft,low output speed can be achieved.

The Designation of Cycloidal Reducers

Example: BL(E)D41-1225-0.37-WB: B series cyclo drive gearboxL: Vertical mounted with flange, Shaft downward(E): None-one stage, E-two stage, S-three stageD:Standard electric motors41: Model number 411225: Speed Reduction Ratio

0.37: Electric motor power:0.37kwW: Mounting way.

Basic Parameters

Power range: 0.25 – 90kW

Output speed(r/min): 0.011 – 161Output Torque(N.M): Top to 22920N.m

All models of this cycloidal motor reducer are

BW0、、BWD0、BW1、BWD1、BW2、BWD2、BW3、BWD3、BW4、BWD4、BW5、BWD5、BW6、BWD6、BW7、BWD7、BW8、BWD8、BW9、BWD9、BL0、BLD0、BL1、BLD1、BL2、BLD2、BL3、BLD3、BL4、BLD4、BL5、BLD5、BL6、BLD6、BL7、BLD7、BL8、BLD8、BL9、BLD9、

BWE20、BWED20、BWE30、BWED30、BWE31、BWED31、BWE41、BWED41、BWE42、BWED42、BWE52、BWED52、BWE53、BWED53、BWE63、BWED63、BWE74、BWED74、BWE85、BWED85、BWE95

BW12、BWD12、BW15、BWD15、BW18、BWD18、BW22、BWD22、BW27、BWD27、BW33、BWD33、BW39、WD39、BW45、BWD45、BW55、BWD55、

BL12、BLD12、BL15、BLD15、BL18、BLD18、BL22、BLD22、BL27、BLD27、BL33、BLD33、BL39、LD39、BL45、BLD45、BL55、BLD55、

BWE1512、BWED1512、BWE1812、BWED1812、BWE2212、BWED2212、BWE2215、BWED2215、BWE2715、BWED2715、BWE2718、BWED2718、BWE3318、BWED3318

XW0、XW1、XW2、XW3、XW4、XW5、XW6、XW7、XW8、XW9、XW10、XW11、XW12

XWD1、XWD2、XWD3、XWD4、XWD5、XWD6、XWD7、XWD8、XWD9、XWD10、XWD11、XWD12

XL0、XL1、XL2、XL3、XL4、XL5、XL6、XL7、XL8、XL9、XL10、XL11、XL1

XLD1、XLD2、XLD3、XLD4、XLD5、XLD6、XLD7、XLD8、XLD9、XLD10、XLD11、XLD12

XWED20、XWED32、XWED42、XWED53、XWED63、XWED74、XWED84、XWED85、XWED95、XWED106、XWED128

XLE20、XLE32、XLE42、XLE53、XLE63、XLE74、XLE84、XLE85、XLE95、XLE106、XLE128

XLED20、XLED32、XLED42、XLED53、XLED63、XLED74、XLEDK84、XLED85、XLED95、XLED106、XLED128

XJ0、JXJ0、XJ1、JXJ1、XJ2、JXJ2、XJ3、JXJ3、XJ4、JXJ4、XJ5、JXJ5、XJ6、JXJ6、

XJL0、JXJL0、XJL1、JXJL1、XJL2、JXJL2、XJL3、JXJL3、XJL4、JXJL4、XJL5、JXJL5、XJL6、JXJL6、XJE10、JXJE10、XJE20、JXJE20、XJE31、JXJE31、XJE41、JXJE41、XJE42、JXJE42、XJE52、JXJE52、XJE53、JXJE53、XJE63、JXJE63、

XJLE10、JXJLE10、XJLE20、JXJLE20、XJLE31、JXJLE31、XJLE41、JXJLE41、XJLE42

Reduction ratio mainly is 7,9,11,17,23,29,35,43,59,71,87,99,121,187,289,391,493,595,731,841,1003,1225,1505,1849,2065,2537,3481,4189,5133,7569.

Paint Color: Various

Material: Rugged cast iron or ductile housings

Lubrication: Grease or oil lubricated models available.

Seals: Nitrile material, dual lipped, double output seals available.

Working: 24 hours continuous available and shaft forward reverse

Reducer Reduction: Internal planetary gear mechanism with trochoidal curved tooth profile.

Atmosphere: Well ventilated location, free of corrosive gases, explosive gases, vapors and dust

Application :

• Conveyors • Sawmills and Wood Mills • Food Machinery • Wastewater Treatment• Mixers • Steel Mills • Automotive Plants • Construction Equipment• Paper Mills • Recycling Machines • Poultry Plants • Processing Plants• Oil Press Machine • Rotary Feeder

What are our unique advantages in making Cycloidal Reducers your choice factory infrastructure investment?

we can help you:

● Providing proper type gearbox and combined gearbox to meet your application needs;

● Better managing maintenance cost and lifting operation efficiency;

● Improving production capacity and boosting economic profitability.

cycloidal gear reducer is widely used in many industries such as Textile manufacturing and food industry. it is small but very good quality. This kind of gear reducer can divided into three parts, the input , the reduction part and the output shaft. There is a double eccentric locking collars in the input part. when input shaft turns a round, the eccentric locking collars will also turns a round so that transfer to the reduction part. to make the output shaft turns. so it make torques. Efficiency can get to 95% . Usually, there are two mounting way and this is vertical mounting.It can be widely used in industry of Coal, steel, machinery, chemical, textile, mixer etc. This can have one stage, two stages and three stages reduction gear. If you want it with flange, we can make. the price with flange or without flange is same.

How to choose a proper type of Gearbox : It is recommended that as much as possible of the following information be given in the enquiry or order so that a check can be made and advice given on the most suitable size of Worm Speed Reducer for any application.1.Type of prime mover.2. Horse-power of prime mover.3. Output torque required from driven member. 4. Input speed of gear unit.5. Output speed of gear unit. 6. Configuration of drive required and shaft disposition. 7. Total daily hours of running. If running is intermitteTo get the type-choose reference,please contact our technical rep or sales rep .

Characteristics:

1.Cycloid reducer big reduction ratio, high efficiency: a reduction gear ratio is 9~87, the two-stage reduction gear ratio is 121 ~ 5133, multistage combination can reach tens of thousands, and the needle tooth meshing line type rolling friction, the meshing surface no relative sliding, so a reduction efficiency of 94%.

2.Pin wheel reducer smooth running, low noise: the teeth contact at the same time when in operation, the coincidence degree high, stable running, strong overload capacity, low vibration and noise, a variety of models, small noise.

3. The use of reliable, long life: because the main part is made of high carbon alloy steel quenching (HRC58-62), and then grinding, and cycloid gear and pin gear set mesh transfer to the pin gear form rolling friction pair, friction coefficient is small, so that the meshing zone no relative sliding, wear small, so durable.

4. Compact structure, small volume: compared with other reducer with the power of the above weight, small volume 1/3, as is the planetary transmission, the input shaft and the output shaft in the same axis, in order to obtain the smallest possible size.

Our Company

HangZhouYinxin Electromechanical Facilities Co. Ltd

HangZhouYinxin Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for danger in times of peace, unremitting……

Application area

What do our customers use Cycloidal Drives for?Cycloidal Drive Gear Motor for Travel Motors in Automated Guided VehiclesCycloidal Drive Gear Motor for Production Line Conveyor SystemsCycloidal Drive Gear Motor for Chemical Industry Mixers & AgitatorsCycloidal Drive Gear Motor for Pumping, Cooling & Lubrication SystemsCycloidal Drive Gear Motor for Metalworking MachinesCycloidal Drive Gear Motor for Construction MacIt is our aim to supply a vast range of quality products at affordable prices, provide the best service for customers satisfied and contribute to our continued improvement. hineryGear Motor for Water Treatment PlantsGear Motor for Recycling MachineryGear Motor for Steel Industry ProductionCycloidal Drive Gear Motor for Sawmills and Woodworking MachinesCycloidal Drive Gear Motor for Food & Sugar Industry Production LinesCycloidal Drive Gear Motor for Heavy Materials Transportation in Rolling MillsCycloidal Drive Gear Motor for Paper Industry Production Lines

Certifications

Sales territory

Packing & Delivery

|

Packaging |

||

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

|

Weight |

1.2 T |

|

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

|

Packaging |

||

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

|

Weight |

1.2 T |

|

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manuA power take-off or power takeoff (PTO) is any of several methods for taking power from a power source, such as a running engine, and transmitting it to an application such as an attached implement or separate machine.facturer in ZJ China.welcome to our factory to have a visit.

Q2: How we select models and specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: We will give the best price we can base on your needs and the quantities.

Q4: How long should I wait for the feedback after I send the enquiry?

A: Within 12 hours.

Q5: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.