Product Description

|

Product Name |

Custom Stainless Steel Long CHINAMFG Gear Shafts |

|||

|

Material |

1)Metal:Stainless steel,Steel(Iron,)Brass,Copper,Aluminum2)Plastic:POM,Nylon,ABS,PP 3)OEM according to your request |

|||

|

Surface treatment |

Anodized different color,Mini polishing&brushing,Electronplating(zinc plated,nickel plated,chrome plated),Power coating&PVD |

|||

|

Tolerance |

±0.01mm |

|||

|

process |

Machining |

|||

|

Certificate |

ISO9001:2015,SGS, ROHS,ISO9001:2015 |

|||

|

Size |

According to your drawing(stp,dwg,igs,pdf),or sample,provide custom service |

|||

ZheZheJiang nlead Precision Co., Ltd. which focuses on CNC machining, including milling, turning, auto-lathe turning,holing,

grinding, heat treatment from raw materials of bars, tube, extruded profiles, blanks of cold forging & hot forging, aluminum

die casting.

We provide one-stop service, from professional design analysis, to free quote, fast prototype, IATF16949 & ISO14001

standard manufacturing, to safe shipping and great after-sales services.During 16 years, we have win lots of trust in the

global market, most of them come from North America and Europe.

Now you may have steady customers, and hope you can keep us in the archives to get more market news.

Sunlead produce all kinds of machining parts according to customer’s drawing, we can produces stainless steel Turned

parts,carbon steel Turned parts, aluminum turned parts,brass & copper turned parts. Please feel free to send inquiry to

us, and our professional sales manager will get back to you ASAP!

Our advantage:

*Specialization in CNC formulations of high precision and high quality

*Independent quality control department

*Control plan and process flow sheet for each batch

*Quality control in all whole production

*Meeting demands even for very small quantities or single units

*Short delivery times

*Excellent price-quality ratio

*Absolute confidentiality

*Various materials (stainless steel, iron, brass, aluminum, titanium, special steels,

industrial plastics)

1. Are you a factory or a trading company?

A: We are a factory specializing in CNC processing and automatic manufacturing.

2. How’s the package?

A: Normally are Carton box+wooden box, but also we can pack it according to your requireme

3. How long can I get some samples for checking and what about the price?

A: Normaly samples will be done within 1-2 days (automatic machining parts) or 3-5 day (cnc machining parts).

Thesample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your

order quantity is good.

4. How is the warranty of the products quality control?

: We hold the tightend quality controlling from very begining to the end and aim at 100% error free.

5.How to get an accurate quotation?

♦ Drawings, photos or samples of products.

♦ Detailed sizes of products.

♦ Material of products.

♦ Surface treatment of products.

♦ Ordinary purchasing quantity. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Condition: | New |

| Color: | Red, Silver, Yellow |

| Samples: |

US$ 16.98/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What factors should be considered when selecting the right PTO shaft for an application?

When selecting the right Power Take-Off (PTO) shaft for an application, several factors need to be considered to ensure optimal performance, safety, and compatibility. PTO shafts are crucial components that transmit power from a power source to driven machinery or equipment. Here are the key factors to consider when selecting the appropriate PTO shaft for an application:

1. Power Requirements: The power requirements of the driven machinery play a vital role in determining the appropriate PTO shaft. Consider the horsepower (HP) or kilowatt (kW) rating of the power source and ensure that the PTO shaft can handle the required power transmission. It is essential to match the power capacity of the PTO shaft with the power output of the power source to ensure efficient and reliable operation.

2. Speed and Torque Requirements: Consider the speed and torque requirements of the driven machinery. Determine the desired rotational speed and torque levels necessary for the equipment to operate effectively. Some applications require specific speed or torque ratios, while others may require variable speeds. Ensure that the selected PTO shaft can handle the required speed and torque range to provide the necessary power transfer.

3. Shaft Type and Design: Evaluate the type and design of the PTO shaft to ensure compatibility with the application. Consider factors such as the distance between the power source and the driven machinery, the need for angular misalignment, and the flexibility of movement required. Different shaft types, such as standard, telescopic, or Constant Velocity (CV) shafts, offer varying capabilities to accommodate different application requirements.

4. Safety Considerations: Safety is a critical factor when selecting a PTO shaft. Assess the safety features provided by the PTO shaft, such as protective guards, shear bolt mechanisms, or other safety devices. Protective guards should be in place to prevent accidental contact with the rotating shaft. Shear bolt mechanisms can protect the driveline components from damage in case of excessive torque or sudden resistance. Prioritize safety features that align with the specific hazards and risks associated with the application.

5. Application Specifics: Consider the unique requirements of the application. Factors such as the type of machinery, industry sector, environmental conditions, and operating conditions should be taken into account. For example, agricultural applications may require PTO shafts that can handle debris and dirt accumulation, while industrial applications may require PTO shafts with high corrosion resistance or special sealing to protect against contaminants.

6. Compatibility and Interchangeability: Ensure that the selected PTO shaft is compatible with the power source and the driven machinery. Consider factors such as the shaft diameter, spline size, and connection type. Check if the PTO shaft adheres to industry standards and if it can be easily interchanged with other compatible components in case of replacement or upgrading needs. Compatibility and interchangeability can simplify maintenance and reduce downtime.

7. Manufacturer and Quality: Choose a reputable manufacturer or supplier to ensure the quality and reliability of the PTO shaft. Look for manufacturers with a track record of producing high-quality PTO shafts that meet industry standards and regulations. Consider factors such as warranty, after-sales support, and availability of spare parts when making a selection.

By considering these factors, you can select the right PTO shaft that meets the power, speed, torque, safety, and application requirements. It is advisable to consult with experts, such as equipment manufacturers or PTO shaft specialists, to ensure an optimal match between the PTO shaft and the application.

Are there any limitations or disadvantages associated with PTO shafts?

While PTO (Power Take-Off) shafts offer numerous advantages in terms of power transfer and versatility, they also have certain limitations and disadvantages. It’s important to consider these factors when using PTO shafts to ensure safe and efficient operation. Here’s a detailed explanation of some limitations and disadvantages associated with PTO shafts:

1. Safety Hazards: One of the primary concerns with PTO shafts is the potential for safety hazards. PTO shafts rotate at high speeds and can pose a significant risk if not properly guarded or handled. Accidental contact with an exposed or inadequately shielded PTO shaft can result in severe injuries, including entanglement, amputation, or even fatalities. It is crucial to follow safety guidelines, implement proper guarding, and ensure that operators are well-trained on safe handling practices to mitigate these risks.

2. Maintenance and Lubrication: PTO shafts require regular maintenance and lubrication to ensure optimal performance and longevity. The moving parts, such as universal joints and splines, need to be inspected, cleaned, and lubricated at recommended intervals. Neglecting maintenance can lead to premature wear, decreased efficiency, and potential failures. Proper maintenance practices, including regular inspections and timely lubrication, are essential to mitigate these issues.

3. Alignment and Angles: PTO shafts rely on proper alignment and angles to ensure efficient power transfer. Misalignment or excessive angles between the power source and driven machinery can cause increased wear and strain on the components, leading to premature failure. Ensuring proper alignment and angle adjustment, using adjustable sliding yokes or other means, is important to prevent excessive stress on the PTO shaft and associated equipment.

4. Length Limitations: PTO shafts have limitations on their maximum and minimum length due to engineering constraints. The telescoping design allows for some adjustment, but there is a practical limit to how much the shaft can extend or retract. If the distance between the power source and driven machinery exceeds the maximum or falls below the minimum length of the PTO shaft, alternative solutions or modifications may be required. In some cases, additional components such as drive shaft extensions or gearboxes may be necessary to bridge the distance.

5. Compatibility: While manufacturers strive to ensure compatibility, there can still be challenges in finding the right PTO shaft for specific equipment configurations. Equipment may have unique requirements in terms of spline sizes, torque ratings, or connection methods that may not be readily available or compatible with off-the-shelf PTO shafts. Customization may be required to address these compatibility issues, which can result in increased costs or lead times.

6. Noise and Vibrations: PTO shafts in operation can generate significant noise and vibrations, especially at higher speeds. This can be a nuisance for operators and may require additional measures to reduce noise levels or dampen vibrations. Excessive vibrations can also affect the overall performance and lifespan of the PTO shaft and connected equipment. Implementing vibration dampeners or using flexible couplings can help mitigate these issues.

7. Power Limits: PTO shafts have specific power limits based on their design, materials, and components. Exceeding these power limits can lead to premature wear, component failures, or even shaft breakage. It is crucial to understand and adhere to the recommended power ratings for PTO shafts to ensure safe and reliable operation. In some cases, upgrading to a higher-capacity PTO shaft or implementing additional power transmission components may be necessary to accommodate higher power requirements.

8. Complex Installation and Removal: Installing and removing PTO shafts can be a complex process, especially in confined spaces or when dealing with heavy equipment. It may require aligning splines, engaging couplings, and securing locking mechanisms. Improper installation or removal techniques can lead to damage to the shaft or associated equipment. Proper training, handling equipment, and following manufacturer guidelines are essential to simplify and ensure the safe installation and removal of PTO shafts.

Despite these limitations and disadvantages, PTO shafts remain widely used and valuable components for power transfer in various industries. By addressing these considerations and implementing proper safety measures, maintenance practices, and alignment procedures, the potential drawbacks of PTO shafts can be effectively mitigated, allowing for safe and efficient operation.

Can you explain the different types of PTO shafts and their applications?

PTO shafts (Power Take-Off shafts) come in various types, each designed for specific applications and requirements. The different types of PTO shafts offer versatility and compatibility with a wide range of machinery and implements. Here’s an explanation of the most common types of PTO shafts and their applications:

1. Standard PTO Shaft: The standard PTO shaft, also known as a splined shaft, is the most common type used in agricultural and industrial machinery. It consists of a solid steel shaft with splines or grooves along its length. The standard PTO shaft typically has six splines, although variations with four or eight splines can be found. This type of PTO shaft is widely used in tractors and various implements, including mowers, balers, tillers, and rotary cutters. The splines provide a secure connection between the power source and the driven machinery, ensuring efficient power transfer.

2. Shear Bolt PTO Shaft: Shear bolt PTO shafts are designed with a safety feature that allows the shaft to separate in case of overload or sudden shock to protect the driveline components. These PTO shafts incorporate a shear bolt mechanism that connects the tractor’s power take-off to the driven machinery. In the event of excessive load or sudden resistance, the shear bolt is designed to break, disconnecting the PTO shaft and preventing damage to the driveline. Shear bolt PTO shafts are commonly used in equipment that may encounter sudden obstructions or high-stress situations, such as wood chippers, stump grinders, and heavy-duty rotary cutters.

3. Friction Clutch PTO Shaft: Friction clutch PTO shafts feature a clutch mechanism that allows for smooth engagement and disengagement of the power transfer. These PTO shafts typically incorporate a friction disc and a pressure plate, similar to a traditional vehicle clutch system. The friction clutch allows operators to gradually engage or disengage the power transfer, reducing shock loads and minimizing wear on the driveline components. Friction clutch PTO shafts are commonly used in applications where precise control of power engagement is required, such as in hydraulic pumps, generators, and industrial mixers.

4. Constant Velocity (CV) PTO Shaft: Constant Velocity (CV) PTO shafts, also known as homokinetic shafts, are designed to accommodate high angles of misalignment without affecting power transmission. They use a universal joint mechanism that allows for smooth power transfer even when the driven machinery is at an angle relative to the power source. CV PTO shafts are frequently used in applications where the machinery requires a significant range of movement or articulation, such as in articulated loaders, telescopic handlers, and self-propelled sprayers.

5. Telescopic PTO Shaft: Telescopic PTO shafts are adjustable in length, allowing for flexibility in equipment configuration and varying distances between the power source and the driven machinery. They consist of two or more concentric shafts that slide within each other, providing the ability to extend or retract the PTO shaft as needed. Telescopic PTO shafts are commonly used in applications where the distance between the tractor’s power take-off and the implement varies, such as in front-mounted implements, snow blowers, and self-loading wagons. The telescopic design enables easy adaptation to different equipment setups and minimizes the risk of the PTO shaft dragging on the ground.

6. Gearbox PTO Shaft: Gearbox PTO shafts are designed to adapt power transmission between different rotational speeds or directions. They incorporate a gearbox mechanism that allows for speed reduction or increase, as well as the ability to change rotational direction. Gearbox PTO shafts are commonly used in applications where the driven machinery requires a different speed or rotational direction than the tractor’s power take-off. Examples include grain augers, feed mixers, and industrial equipment that requires specific speed ratios or reversing capabilities.

It’s important to note that the availability and specific applications of PTO shaft types may vary based on regional and industry-specific factors. Additionally, certain machinery or implements may require specialized or custom PTO shafts to meet specific requirements.

In summary, the different types of PTO shafts, such as standard, shear bolt, friction clutch, constant velocity (CV), telescopic, and gearbox shafts, offer versatility and compatibility with various machinery and implements. Each type of PTO shaft is designed to address specific needs, such as power transfer efficiency, safety, smooth engagement, misalignment tolerance, adaptability, and speed/direction adjustment. Understanding the different types of PTO shafts and their applications is crucial for selecting the appropriate shaft forthe intended machinery and ensuring optimal performance and reliability.

editor by CX 2024-03-19

China high quality Front Drive Shaft Weld Gear Round Bore Yoke Forged Cast Steel Universal Joint Splined Slip Yoke U-Joint End Yoke for Agricultural Pto Shaft Connect

Product Description

Front Drive shaft weld gear round bore Yoke forged cast steel universal joint Splined Slip Yoke u-joint end yoke For Agricultural Pto Shaft Connect

Application of Splined Slip Yoke

Splined slip yokes are used in a variety of applications, including:

- Automotive: Splined slip yokes are used in automotive applications, such as transmissions, differentials, and driveshafts.

- Machine tools: Splined slip yokes are used in machine tools to provide a connection between the machine tool and the power source.

- Robotics: Splined slip yokes are used in robotics to provide a connection between the robot and the end effector.

- Aerospace: Splined slip yokes are used in aerospace applications, such as aircraft engines and landing gear systems.

- Construction: Splined slip yokes are used in construction equipment, such as excavators and cranes.

- Medical: Splined slip yokes are used in medical devices, such as surgical robots and endoscopes.

Splined slip yokes offer a number of advantages over other types of connections, including:

- High strength: Splined slip yokes are very strong, making them ideal for applications where high torque is required.

- Low friction: Splined slip yokes have low friction, which helps to reduce wear and tear.

- Easy to install: Splined slip yokes are relatively easy to install, which makes them a cost-effective option.

As a result of these advantages, splined slip yokes are becoming increasingly popular in a wide variety of applications.

Here are some specific examples of how splined slip yokes are used in automotive applications:

- Transmissions: Splined slip yokes are used to connect the transmission to the driveshaft. The splines on the yoke mesh with the splines on the transmission output shaft, which allows the driveshaft to rotate independently of the transmission.

- Differentials: Splined slip yokes are used to connect the differential to the driveshaft. The splines on the yoke mesh with the splines on the differential output shaft, which allows the driveshaft to rotate independently of the differential.

- Driveshafts: Splined slip yokes are used to connect the driveshaft to the transmission and the differential. The splines on the yoke mesh with the splines on the transmission output shaft and the differential output shaft, which allows the driveshaft to rotate independently of both the transmission and the differential.

Splined slip yokes are an important part of many automotive applications. They provide a strong, low-friction connection between the transmission, differential, and driveshaft. This helps to ensure that the power from the engine is transferred to the wheels efficiently and without damage.

Products Description

1.Forged high quality alloy steel cross is case hardened to provide good wear resistance and maximum service life. Pre-installed grease fitting in the cross saves time, prevents installation damage and allows for easy U-Joint maintenance.

2.Forged high strength steel cups are case hardened for strength and durability. Cup face and outer diameter are precision ground to provide precise fit, lock up and balance ability.

3.High carbon steel needle bearings are through hardened and precision ground using a optimized crowning profile for maximum life and load carrying capacity.

4.Seals are made out of high quality nitrile rubber for optimal grease retention and contaminant exclusion. Multi-lip seal is pliable, yet tough and tear resistant.

5.All U-Joints are pre-lubricated with a premium, high temperature grease that performs well in a wide temperature range and provides a long service life.

Company Profile

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Installation Guide |

|---|---|

| Warranty: | 6 Years |

| Condition: | New |

| Color: | Natural Color |

| Certification: | CE |

| Structure: | Single |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can PTO shaft yokes be customized for specific equipment or attachment needs?

Yes, PTO shaft yokes can be customized to meet specific equipment or attachment needs. Manufacturers often offer customization options to ensure compatibility and optimal performance in diverse applications. Here are some ways in which PTO shaft yokes can be customized:

1. Shaft Size and Spline Count: PTO shaft yokes can be customized to match the specific shaft size and spline count of the power source and the implement. This ensures a proper fit and secure connection, allowing efficient power transmission.

2. Connection Methods: Yokes can be customized to accommodate different connection methods, such as pin-type, quick-detach, or threaded connections. This flexibility allows for easy attachment and detachment of implements, enhancing convenience and versatility.

3. Length and Offset: In some cases, the length or offset of the PTO shaft yoke needs to be customized to align the power source and the implement correctly. Manufacturers can modify the yoke’s dimensions to ensure optimal alignment and minimize stress on the driveline.

4. Material and Coating: Customization options may include the choice of materials and coatings for PTO shaft yokes. Different materials, such as steel alloys or specialized composites, can be selected based on the specific application requirements, providing enhanced strength, durability, or corrosion resistance.

5. Safety Features: Depending on the equipment or attachment needs, additional safety features can be incorporated into the customized PTO shaft yokes. This may include the integration of specific overload protection mechanisms, such as shear pins, slip clutches, or torque limiters.

6. Specialized Requirements: In certain industries or niche applications, specialized requirements may arise. Manufacturers can work with customers to design and engineer PTO shaft yokes that meet these unique needs, such as high-speed applications, extreme load conditions, or specific regulatory standards.

It is important to note that customization options may vary among manufacturers, and additional costs and lead times may be associated with custom orders. Working closely with the manufacturer or a knowledgeable supplier can help determine the feasibility and available customization options for specific equipment or attachment needs.

What maintenance practices are essential for prolonging the lifespan of PTO shaft yokes?

Maintaining proper maintenance practices is crucial for prolonging the lifespan of PTO (Power Take-Off) shaft yokes. By following these essential maintenance practices, you can ensure the longevity and optimal performance of the yokes:

1. Regular Inspection:

Perform regular visual inspections of the PTO shaft yokes to check for signs of wear, damage, or misalignment. Look for any cracks, distortion, or excessive play in the joints. Inspect the splines and ensure they are clean and free from debris. Detecting and addressing any issues early can prevent further damage and prolong the lifespan of the yokes.

2. Lubrication:

Proper lubrication is vital for reducing friction and wear in the PTO shaft yokes. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant. Apply lubrication to the splines, bearings, and any other moving parts as specified. Regular lubrication helps maintain smooth operation and minimizes the risk of premature wear or failure.

3. Cleaning:

Keep the PTO shaft yokes clean and free from dirt, debris, and excessive buildup of grease. Use a suitable cleaning agent and a brush to remove any contaminants. Clean the splines thoroughly to ensure proper engagement and torque transmission. Regular cleaning prevents the accumulation of abrasive particles that can cause accelerated wear and damage to the yokes.

4. Shaft Alignment:

Ensure proper alignment between the power source and the driven equipment. Misalignment can increase stress on the PTO shaft yokes and lead to premature wear. Use alignment tools and techniques to align the shafts correctly, minimizing angular and axial misalignment. Proper alignment reduces the load on the yokes and helps maintain their integrity and longevity.

5. Torque Checks:

Periodically check the torque on the PTO shaft yokes’ fasteners, such as bolts or retaining nuts. Over time, these fasteners can loosen due to vibrations or dynamic loading. Use a torque wrench to ensure the fasteners are tightened to the manufacturer’s specifications. Proper torque helps maintain the integrity of the yokes and prevents unexpected failures.

6. Protective Shielding:

Inspect and maintain any protective shielding or guards that are installed to cover rotating components or exposed parts of the PTO shaft yokes. Ensure that the shielding is intact, securely mounted, and free from damage. Protective shielding prevents accidental contact with moving parts and enhances safety while also protecting the yokes from external elements.

7. Manufacturer Guidelines:

Follow the maintenance guidelines provided by the manufacturer of the PTO shaft yokes. Manufacturers often provide specific instructions, recommendations, and maintenance schedules tailored to their products. Adhering to these guidelines ensures that the yokes are maintained in the best possible condition, maximizing their lifespan.

By implementing these essential maintenance practices, you can prolong the lifespan of PTO shaft yokes, minimize downtime, and ensure reliable and efficient operation in various applications.

What factors should be considered when selecting the right PTO shaft yoke for an application?

When selecting the right PTO (Power Take-Off) shaft yoke for an application, several factors should be considered to ensure compatibility, reliability, and optimal performance. Here are the key factors to consider:

1. Power Requirements:

Determine the power requirements of the application, including the torque and speed specifications. Ensure that the selected PTO shaft yoke is capable of handling the expected power output from the power source and can safely transmit the required torque and speed without exceeding its limitations.

2. Shaft Size and Spline Count:

Match the PTO shaft yoke to the size and spline count of the PTO shaft. Consider the outer diameter and spline count of both the shaft and the yoke to ensure compatibility and a proper fit. Proper shaft and spline size matching is crucial for efficient power transmission and to prevent slippage or damage.

3. Application Type:

Consider the specific application in which the PTO shaft yoke will be used. Different applications may have unique requirements, such as agricultural machinery, construction equipment, or industrial applications. Ensure that the selected yoke is suitable for the intended application and can withstand the operating conditions, environment, and workload.

4. Yoke Material and Construction:

Evaluate the material and construction of the PTO shaft yoke. Common materials include steel or forged alloys, which offer durability and strength. Consider factors such as resistance to wear, corrosion, and fatigue to ensure the yoke can withstand the demands of the application.

5. Operating Environment:

Take into account the operating environment and conditions in which the PTO shaft yoke will be used. Factors such as temperature, moisture, dust, and exposure to chemicals or harsh substances can impact the yoke’s performance and longevity. Choose a yoke that is designed to withstand the specific environmental conditions of the application.

6. Safety Considerations:

Consider safety aspects related to the use of the PTO shaft yoke. Ensure that the yoke is compliant with safety standards and regulations, and that it includes appropriate shielding or guarding to prevent accidental contact with rotating parts. Safety should be a priority to minimize the risk of injuries or accidents during operation.

7. Manufacturer or Supplier:

Consider the reputation, reliability, and support provided by the manufacturer or supplier of the PTO shaft yoke. Choose a reputable supplier who offers high-quality products, technical expertise, and good customer support to address any concerns or issues that may arise.

By carefully considering these factors, you can select the right PTO shaft yoke that meets the specific requirements of your application, ensuring compatibility, durability, and optimal performance.

editor by CX 2024-02-12

China high quality Drive Gear Pto and Transmission Shaft Factory Steel Precision Agricultural Machinery Use Power Transmission Shaft Transmission Shaft Factory Steel Precision39

Product Description

Parameter specifications

| Certification | Shipment | Quality | material | Company System Certification |

| IATF16949 | in time | high | steel | ISO9001 |

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CHINAMFG Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample 40000

|

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there variations in PTO shaft designs for different types of machinery?

Yes, there are variations in PTO (Power Take-Off) shaft designs to accommodate the specific requirements of different types of machinery. PTO shafts are highly versatile and adaptable components used to transfer power from a power source, such as a tractor or engine, to driven machinery or equipment. The design variations in PTO shafts are necessary to ensure compatibility, efficiency, and safety in various applications. Here’s a detailed explanation of the different PTO shaft designs for different types of machinery:

1. Standard PTO Shafts: Standard PTO shafts are the most common design and are widely used in a variety of applications. They typically consist of a solid steel shaft with a universal joint at each end. These universal joints allow for angular misalignment between the power source and the driven machinery. Standard PTO shafts are suitable for applications where the distance between the power source and the driven machinery remains relatively fixed. They are commonly used in agricultural implements, such as mowers, balers, tillers, and seeders, as well as in industrial applications.

2. Telescopic PTO Shafts: Telescopic PTO shafts feature a telescoping design that allows for length adjustment. These shafts consist of two or more concentric shafts that can slide within each other. Telescopic PTO shafts are beneficial in applications where the distance between the power source and the driven machinery varies. By adjusting the length of the shaft, operators can ensure proper power transmission without the risk of the shaft dragging on the ground or being too short to reach the equipment. Telescopic PTO shafts are commonly used in front-mounted implements, snow blowers, self-loading wagons, and other applications where the distance between the power source and the implement changes.

3. CV (Constant Velocity) PTO Shafts: CV PTO shafts incorporate Constant Velocity joints to accommodate misalignment and angular variations. These joints maintain a constant speed and torque transfer even when the driven machinery is at an angle relative to the power source. CV PTO shafts are beneficial in applications where the driven machinery requires flexibility and a wide range of movement. They are commonly used in articulated loaders, telescopic handlers, self-propelled sprayers, and other equipment that requires continuous power transmission while operating at various angles.

4. Gearbox Driven PTO Shafts: Some machinery requires specific speed or torque ratios between the power source and the driven equipment. In such cases, PTO shafts may incorporate gearbox systems. Gearbox driven PTO shafts allow for speed reduction or increase and can change the rotational direction if necessary. The gear ratios in the gearbox can be adjusted to match the speed and torque requirements of the driven machinery. These PTO shafts are commonly used in applications where the power source operates at a different speed or torque level than the equipment it drives, such as in certain industrial manufacturing processes and specialized machinery.

5. High-Torque PTO Shafts: Some heavy-duty machinery requires high torque levels for power transmission. High-torque PTO shafts are designed to handle these demanding applications. They are constructed with reinforced components, including larger diameter shafts and heavier-duty universal joints, to withstand the increased torque requirements. High-torque PTO shafts are commonly used in equipment such as wood chippers, crushers, and heavy-duty agricultural implements that require substantial power and torque for their operation.

6. Safety PTO Shafts: Safety is a crucial consideration when using PTO shafts. Safety PTO shafts incorporate mechanisms to reduce the risk of accidents and injuries. One common safety feature is the use of protective guards that cover the rotating shaft to prevent accidental contact. These guards are typically made of metal or plastic and are designed to shield the rotating components while allowing the necessary movement for power transmission. Safety PTO shafts are used in various applications where the risk of entanglement or accidental contact with the rotating shaft is high, such as in grass mowers, rotary cutters, and other equipment used in landscaping and agriculture.

These are some of the key variations in PTO shaft designs for different types of machinery. The specific design used depends on factors such as the application requirements, power source characteristics, torque levels, movement flexibility, and safety considerations. PTO shaft manufacturers offer a range of designs to ensure compatibility and efficient power transmission in diverse industries and applications.

How do PTO shafts contribute to the efficiency of agricultural operations?

Power Take-Off (PTO) shafts play a crucial role in improving the efficiency of agricultural operations by providing a versatile and reliable power source for various farming equipment. PTO shafts allow agricultural machinery to access power from tractors or other prime movers, enabling the efficient transfer of energy to perform a wide range of tasks. Here’s a detailed explanation of how PTO shafts contribute to the efficiency of agricultural operations:

1. Versatility: PTO shafts offer versatility by allowing the connection of different types of implements and machinery to tractors or other power sources. This versatility enables farmers to use a single power unit, such as a tractor, to operate multiple agricultural implements, including mowers, balers, tillers, seeders, sprayers, and more. The ability to quickly switch between various implements using a PTO shaft minimizes downtime and maximizes efficiency in agricultural operations.

2. Power Transfer: PTO shafts efficiently transfer power from the tractor’s engine to the agricultural implements. The rotating power generated by the engine is transmitted through the PTO shaft to drive the machinery connected to it. This direct power transfer eliminates the need for separate engines or motors on each implement, reducing equipment costs and maintenance requirements. PTO shafts ensure a reliable power supply, allowing agricultural operations to be carried out efficiently and effectively.

3. Increased Productivity: By utilizing PTO shafts, agricultural operations can be performed more quickly and efficiently than manual or alternative power methods. PTO-driven machinery typically operates at higher speeds and with greater power compared to human-operated or manual tools. This increased productivity allows farmers to complete tasks such as tilling, seeding, harvesting, and material handling more efficiently, reducing labor requirements and increasing overall farm productivity.

4. Time Savings: PTO shafts contribute to time savings in agricultural operations. The ability to connect and disconnect implements quickly using standardized PTO shafts allows farmers to switch between tasks rapidly. This saves time during equipment setup, as well as when transitioning between different operations in the field. Time efficiency is particularly valuable during critical farming periods, such as planting or harvesting, where timely execution is essential for optimal crop yield and quality.

5. Reduced Manual Labor: PTO shafts minimize the need for manual labor in strenuous or repetitive tasks. By harnessing the power of tractors or other prime movers, farmers can mechanize various operations that would otherwise require significant physical effort. Agricultural implements driven by PTO shafts can perform tasks such as plowing, mowing, and baling with minimal human intervention, reducing labor costs and improving overall efficiency.

6. Precision and Consistency: PTO shafts contribute to precision and consistency in agricultural operations. The consistent power supply from the PTO ensures uniform operation and performance of the connected machinery. This helps in achieving consistent seed placement, even spreading of fertilizers or chemicals, and precise cutting or harvesting of crops. Precision and consistency lead to improved crop quality, enhanced yield, and reduced waste, ultimately contributing to the overall efficiency of agricultural operations.

7. Adaptability to Various Terrain: PTO-driven machinery is highly adaptable to various types of terrain encountered in agricultural operations. Tractors equipped with PTO shafts can traverse uneven or challenging terrain, allowing implements to operate effectively on slopes, rough fields, or hilly landscapes. This adaptability ensures that farmers can efficiently manage their land, regardless of topographical challenges, enhancing operational efficiency and productivity.

8. Integration with Automation and Technology: PTO shafts can be integrated with automation and technology advancements in modern agricultural practices. Automation systems, such as precision guidance and control, can be synchronized with PTO-driven machinery to optimize operations and minimize waste. Additionally, advancements in data collection and analysis allow farmers to monitor and optimize machine performance, fuel efficiency, and productivity, further enhancing the efficiency of agricultural operations.

By providing versatility, efficient power transfer, increased productivity, time savings, reduced manual labor, precision, adaptability to terrain, and integration with automation and technology, PTO shafts significantly contribute to enhancing the efficiency of agricultural operations. They enable farmers to perform a wide range of tasks with ease, ultimately improving productivity, reducing costs, and supporting sustainable farming practices.

What benefits do PTO shafts offer for various types of machinery?

PTO shafts (Power Take-Off shafts) offer several benefits for various types of machinery in agricultural and industrial applications. They provide a flexible and efficient means of power transmission, enabling machinery to perform specific tasks and functions. Here’s a detailed explanation of the benefits that PTO shafts offer for different types of machinery:

Versatility: PTO shafts contribute to the versatility of machinery by allowing them to be powered by a common power source, such as a tractor or an engine. This means that a single power source can be used to drive multiple implements or machines by simply connecting and disconnecting the PTO shaft. For example, in agriculture, a tractor equipped with a PTO shaft can power various implements such as mowers, balers, tillers, sprayers, and grain augers. Similarly, in industrial applications, PTO shafts enable the use of a single engine or motor to power different machines or equipment, such as generators, pumps, compressors, and industrial mixers.

Efficiency: PTO shafts offer an efficient method of power transfer from the power source to the machinery. By directly connecting the power source to the driven machine, PTO shafts minimize energy losses that may occur with other power transmission methods. This direct power transfer results in improved overall efficiency and performance of the machinery. Additionally, PTO shafts allow for the adjustment of rotational speed and power output to match the requirements of the specific machinery, ensuring optimal operation and reducing unnecessary energy consumption.

Cost Savings: The use of PTO shafts can lead to cost savings in multiple ways. Firstly, by utilizing a single power source to drive multiple machines or implements, the need for separate engines or motors for each piece of equipment is eliminated, reducing capital costs. Secondly, PTO shafts eliminate the requirement for additional fuel or energy sources, as they tap into the existing power source, resulting in lower fuel or energy expenses. Additionally, the versatility offered by PTO shafts allows for improved equipment utilization, maximizing the return on investment.

Flexibility: PTO shafts provide flexibility in terms of equipment setup and configuration. They can be adjusted in length or equipped with telescopic sections, allowing for easy adaptation to different equipment arrangements and varying distances between the power source and the driven machinery. This flexibility enables operators to quickly connect and disconnect the PTO shafts as needed, facilitating efficient equipment changes and reducing downtime. Moreover, the ability to adjust the rotational speed and power output of the PTO shafts adds further flexibility, accommodating the specific requirements of different machinery and applications.

Ease of Use: PTO shafts are relatively easy to use, making them accessible to operators with minimal training. The process of connecting and disconnecting the PTO shafts is straightforward, often involving a simple coupling or locking mechanism. This ease of use enhances equipment operability, allowing operators to quickly switch between different implements or machines without significant effort or time-consuming procedures. Furthermore, the direct power transfer through PTO shafts simplifies equipment operation, as the machinery can be powered by the existing power source without the need for additional controls or power management systems.

Increased Productivity: PTO shafts contribute to increased productivity in agricultural and industrial operations. By enabling the use of versatile machinery configurations, operators can perform a wide range of tasks using a single power source. This eliminates the need for manual labor or the use of multiple machines, streamlining workflow and reducing the time required to complete various operations. The efficiency and reliability of power transfer through PTO shafts also contribute to improved productivity by ensuring consistent and effective operation of machinery, resulting in enhanced output and reduced downtime.

Safety: While not directly related to machinery performance, PTO shafts also offer safety benefits. The implementation of safety shields or guards on PTO shafts helps prevent accidental contact with the rotating shaft, reducing the risk of injuries to operators. These safety features are designed to cover the rotating shaft and universal joints, ensuring that operators cannot come into contact with them during operation. Proper training on PTO shaft operation and adherence to safety guidelines further enhance operator safety when working with PTO-driven machinery.

In summary, PTO shafts offer a range of benefits for various types of machinery. These benefits include increased versatility, improved efficiency, cost savings, flexibility in equipment configurations, ease of use, increased productivity, and enhanced operator safety. PTO shafts play a crucial role in agricultural and industrial applications by enabling the direct power transfer from a common power source to different machines or implements, resulting in optimized performance and operational effectiveness.

editor by CX 2023-09-27

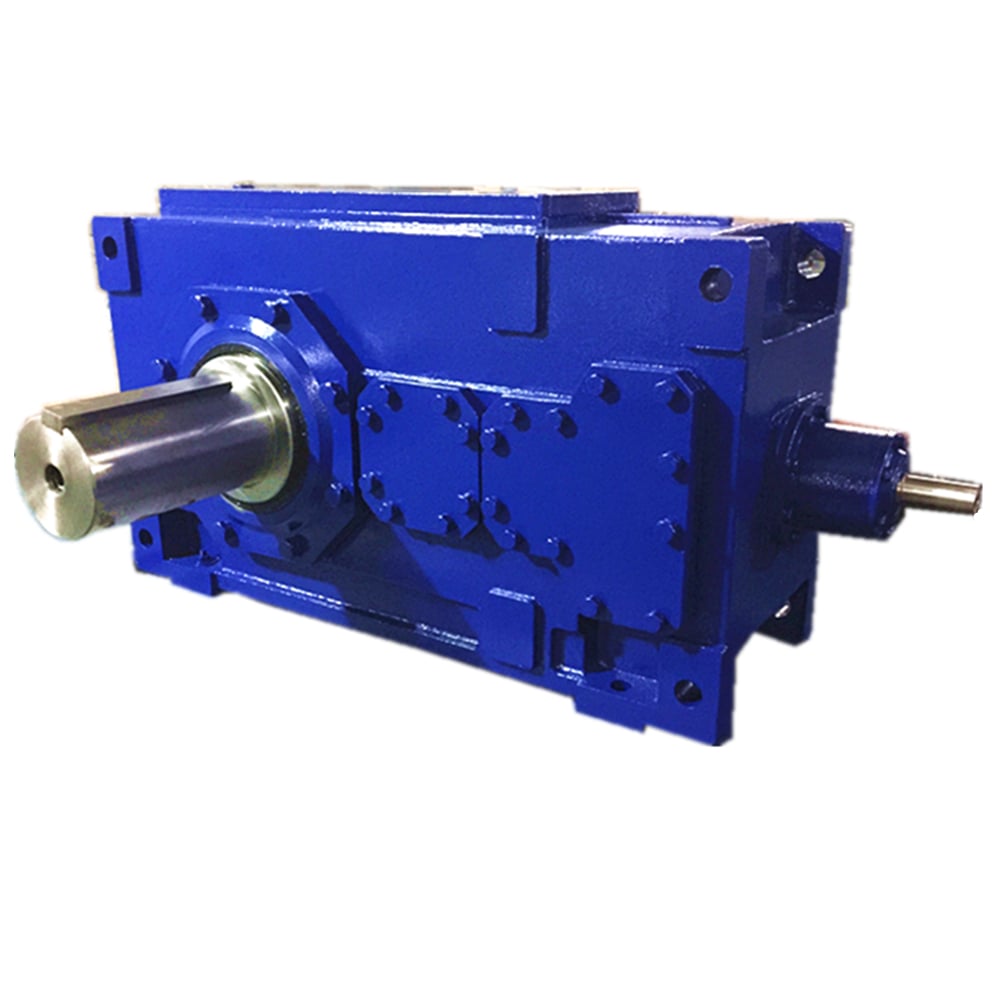

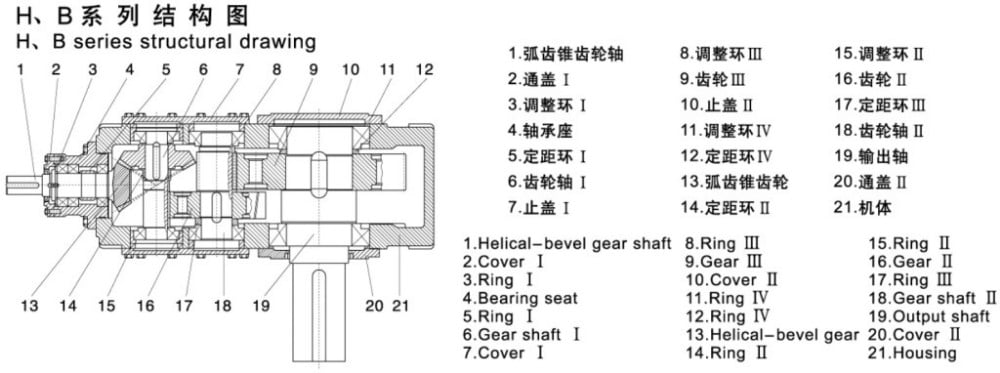

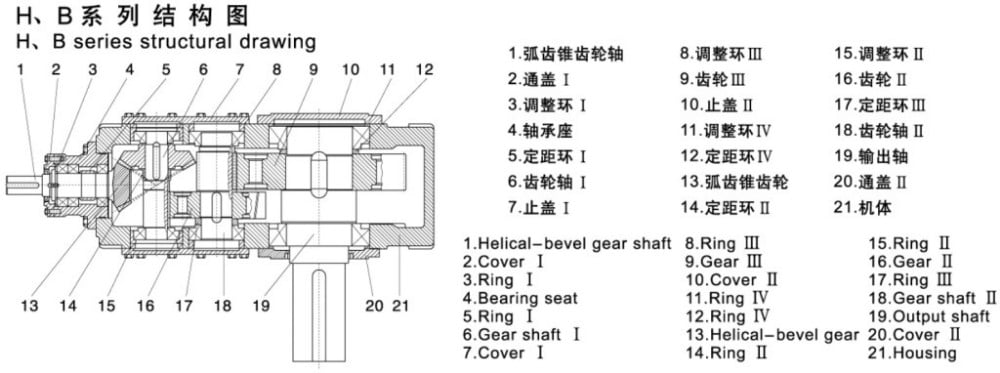

China ND Cast Iron Housing High Rpm Helical Increasing Gear Boxes with Long Shaft (B215+) attaching pto shaft to tractor

Item Description

Merchandise Description

Firm Profile

In 2571, HangZhou CZPT Machinery Co.,ltd was proven by Ms. Iris and her 2 partners(Mr. Tian and Mr. Yang) in HangZhou City, ZHangZhoug province, China, all 3 Founders are engineers who have more than averaged 30 several years of expertise.

We, CZPT equipment proven a complete quality administration method and revenue service network to give clients with high-good quality merchandise and satisfactory service. Our merchandise are marketed in 36 nations around the world and areas in the world, our major marketplace is the European industry.

Manufacturing facility & Workshop

Expert

30 years experience engineman. R&D workplace, Test laboratory, CNC lathe workshop operated by specialists.

Liable

two~10years guarantee. Frame of mind establishes almost everything, particulars decide good results or failure. We are accountable for your goods.

Scientific administration

a hundred% analyzed. Stringent company system and scientific materials management will decrease the mistake fee.

Certifications

We are working on analysis and production all types of gearbox reducer and mechanical elements these eleven years, and have received certificates like ISO9001, several Gearbox Patents, SGS, BV, and so on.

Packaging & Delivery

Sample Space

Via our well-acknowledged brand ND, CZPT Machinery delivers agricultural options to agriculture equipment company and distributors throughout the world by means of a full line of spiral bevel / straight bevel / spur gearboxes, travel shafts, sheet metal, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators and so on. Goods can be custom-made as request.

FAQ

Q: Are you trading organization or company ?

A: We are specifically a factory.

Q: Do you provide samples ? is it cost-free or further ?

A: Indeed, we could offer the sample for totally free charge but do not shell out the value of freight.

Q: How extended is your delivery time ? What is your conditions of payment ?

A: Generally it is 40-forty five times. The time might vary relying on the merchandise and the stage of customization. For regular items, the payment is: 30% T/T in advance, equilibrium before shippment.

Q: What is the specific MOQ or cost for your merchandise ?

A: As an OEM company, we can provide and adapt our merchandise to a wide selection of requirements.Thus, MOQ and price could drastically vary with measurement, content and even more specs For occasion, pricey goods or regular items will typically have a reduce MOQ. Remember to contact us with all related details to get the most precise quotation.

If you have an additional concern, you should come to feel totally free to make contact with us.

|

US $125-165 / Piece | |

50 Pieces (Min. Order) |

###

| Application: | Motor, Machinery, Agricultural Machinery, Industrial, etc |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Shaft T or L Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

###

| Customization: |

Available

|

|---|

|

US $125-165 / Piece | |

50 Pieces (Min. Order) |

###

| Application: | Motor, Machinery, Agricultural Machinery, Industrial, etc |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Shaft T or L Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

###

| Customization: |

Available

|

|---|

Choosing the Right PTO Shaft For Your Tractor

There are a number of different PTO shaft types available for your tractor. These include the North American, German and Italian styles. They are also available in various series, each with different options for bearing diameter and cap-to-cap overall length. To choose the best shaft for your tractor, it’s important to know what kind of tractor you own and the type of PTO that you need.

IID shaft

When it comes to choosing the best IID shaft for your PTO, the selection process can be a challenge. Whether you are replacing the shaft in your own tractor or need to purchase one for a client, there are several factors to consider. The right PTO shaft for your tractor should be compatible with the equipment you currently use. For instance, a shaft that can be used in a farm tractor will fit a different farm tractor than one used in a construction machine.

First of all, a safety shield is a critical part of your IID shaft. The shielding will help keep the entire shaft free of any potential hazards. Typically, shielding will cover the straight part of the shaft, universal joints, and PTO connection. A shield can also help protect you from injury if you accidentally run into the shaft or touch the guard.

A power take off shaft will be the best choice if you are using a tractor for other applications, such as mowing, shredding, or plowing. A PTO shaft is also a crucial part if you own a large tractor or implement. It will allow you to operate your equipment with maximum efficiency.

An IID shaft is designed to slide into another piece when the tractor’s PTO is engaged. A disconnected IID shaft can pull the two pieces apart and cause the tractor to swing uncontrollably when it is engaged. This can cause serious injuries or even death. You should not engage a PTO if you aren’t certain of its strength.

To ensure the safety of the driveline shield, check for proper alignment of the PTO shaft. If it isn’t aligned properly, foreign materials can enter the shaft bearings. A damaged driveline shield can also lead to driveline separation, particularly when the tractor is making sharp turns or downhills. In addition, improper alignment of the drawbar may damage the protective shield that protects the shaft.

Choosing the right PTO series size requires proper measuring of each part. Measure the length of each yoke outside the PTO shaft and determine the appropriate PTO series size. The PTO yoke size chart can be helpful when choosing the correct size for your tractor.

Reverse PTO

Many different applications call for a reverse PTO shaft. These adapters allow the PTO shaft to be turned in the opposite direction of the engine, matching the rotation of the power take-off to the rotation of the equipment it drives. They can be used to space the power take-off away from the transmission case and improve clearance for a direct-coupled pump or driveshaft.

Reverse PTO shafts are available for CZPT . They are designed for six-spline 540-rpm applications. They also offer the option of multi-speed operation. Reversed PTOs are a great option for implements that can get stuck.

Reverse PTOs can be used on most types of PTO. The reverse version has a gearbox that allows it to rotate backward. These are ideal for implements that can get stuck in a field. A reverse PTO shaft makes it possible to work with the implement without having to wait for it to get unstuck.

When using a PTO, it’s important to know which type of gearbox is needed. If you have an older model, you’ll probably need a reverse PTO shaft. These are generally used on older, vintage tractors with ground drive PTO. The ground speed pTO shafts match the speed of the tractor’s final drive, so when the tractor is in reverse, the gearbox will turn backward. This feature will not function if you’re working stationary, though.

A tractor with a reverse PTO is important for a number of reasons. For example, the reverse PTO can help you turn a stuck tractor in the opposite direction, which is useful when a piece of farm equipment becomes stuck in mud or when you need to push a stuck implement back. In addition, it allows you to use the tractor’s power to operate various implements. The reverse PTO also helps you know how much power is needed to run various implements on various terrain.

In addition to being convenient, reverse PTO shafts also help reduce the risk of damage to implements attached to the PTO. It’s vital to keep a PTO shaft in good working order.

Square rigid shaft

When you are looking for a new square rigid PTO shaft, you should consider a few factors. Choosing the right one can be a challenge, as the process is not always simple. For instance, there are a lot of choices when it comes to different brands and interpretations. You can even choose to purchase a square rigid shaft that is not square.

Torsional rigidity is a measure of the ability of a shaft to resist torsional forces. The higher the value of J, the more rigid the shaft will be. For example, a steel shaft has a higher torsional rigidity than an HDPE shaft. The correct value of J can have a big impact on the design decisions.

Another factor to consider is the type of shaft coupling. Rigid shaft couplings are best for shafts that are perfectly aligned. While flexible couplings are flexible enough to accommodate small misalignments, they are not as flexible as the flexible ones. Rigid shaft couplings, which are typically made of metal, are not designed for high-speed rotation.

Rigid couplings are a good choice for a wide range of applications. Rigid couplings are available in many sizes and configurations, and can be used with either a powered or an unsupported shaft. Rigid couplings are also available with keyways to transmit torque.

Torsional rigidity depends on the geometry of the components. A higher torsional rigidity means a shaft is more resilient to twisting. However, excessive twisting can result in unstable performance. As a result, it is important to avoid over-twisting a shaft.

Flange couplings are another option. These couplings have two flanges that are attached to each other with bolts or nuts. They are very similar to split muff couplings and sleeve couplings. The difference is that flange couplings have two flanges – one for the shaft and one for the coupling hub.

If you are thinking about purchasing a square rigid PTO shaft for your tractor, be sure to consider the features that will best serve your specific needs. While you may be considering the price of this new shaft, remember that it is a machine part that could be dangerous.

Economy PTO

There are several standard types of PTO shafts. They can vary in diameter and number of splines, and are designed to work with a specific speed range. The following are the main differences between these types. Choosing the right type for your application will depend on its application. One of the most important considerations to make when choosing a PTO shaft is the ratio between the shaft’s diameter and the toothed wheels that are attached to it.

When choosing a PTO shaft, consider the amount of torque you need. In general, an economy PTO shaft should be able to support a maximum load of 540 Nm. In addition, it should be able to handle a high-speed output. An economy PTO shaft may need less torque than a high-performance model.

Economy PTO shafts come in two basic styles: North American and Italian. These two types are designed to provide constant-speed output and balance the power input of a tractor. There are also various other styles of PTO shafts available, including square and rectangular half-shaft assemblies. You can also purchase extra parts to repair a worn PTO shaft.

The control/monitoring unit in a PTO includes a screen display and a manual control for selecting engaged or disengaged PTO states. In addition, there is a switch in the cab mounted control unit 14 that selects normal and economy modes when driving the PTO. These modes utilize different gears to achieve the desired PTO shaft revs.

To select the right PTO speed, select the lever in economy mode and increase the throttle to the appropriate rpm. The PTO speed should be 540 RPM. The control/monitoring unit 14 will use this information to adjust the clutch control parameters. In addition to the PTO speed, it will also display the torque on the PTO shaft.

Economy PTO shafts are ideal for a variety of applications. These PTOs allow the tractor to run at lower rpms, thereby reducing noise and vibrations. They are typically available in both hydraulic and mechanical types.

editor by czh 2022-12-22

China manufacturer & factory supplier for SWL in Dehradun India series manual worm machine gear nut superior quality ball screw jack speed reducer With high quality best price & service

manufacturing unit of roller chains. Conveyor chains, engineered chains, silent chains, and tabletop chains are also obtainable. Other power transmission products consist of pillow blocks, conveyor idlers, conveyor pulleys, travel shafts, gear racks, gear reducers, gears, overrunning clutches, motor bases, pulleys, screw conveyors, shaft couplings, sheaves, velocity reducers, sprockets, tapered bushings, tensioners, torque limiters, and universal joints. Providers this kind of as bearing reconditioning and repair, ball screw repair, customized agreement machining, gearbox restore and overrunning clutch restore providers are accessible. Roller chains can be employed in conveyor and machinery manufacturing, industrial processing, machine rebuilding, squander h2o, sand and gravel, resource and die, metal, metals and scrap processing industrial apps.In 2000, EPG took the guide in gaining ISO14001 setting administration certificate and thereafter handed the inspection of clean creation and recycling financial system, winning the title of “Zhejiang Eco-friendly Enterprise”.

Overview

Fast Details

- Relevant Industries:

-

Building Substance Retailers

- Gearing Arrangement:

-

Worm

- Output Torque:

-

two.6-1195N.M

- Enter Speed:

-

1400rpm

- Output Velocity:

-

14-280r/min

- Location of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

- Certification:

-

ISO9001-2008

- Lifting Potential:

-

As request

- Lifting Peak(mm):

-

As request

- All round Width(mm):

-

As request

- Gear substance:

-

Reduced carbon substantial alloy metal

- Warmth therapy:

-

Carburising, quenching, equipment grinding

- Diameter & Duration of Screw:

-

Designed as ask for

- Bearing:

-

C&U

- gear precision grade:

-

din 4

Offer Capability

- Provide Capability:

- five hundred Unit/Models for each Month

Packaging & Shipping

- Packaging Details

- Standard exporting package deal

- Port

- Ningbo Port, Shanghai Port

On-line Customization

EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting resources.

SWL collection manual worm equipment gear nut excellent quality ball screw jack velocity reducer

Solution Description

Benefit:

SWL Worm-bolt lifter has the features of compacted framework, light-weight and transportable, flexible, trustworthy, long service daily life, straightforward to set up, and self-locking even though stop.

Application Industries:

SWL series screw jacks are extensively utilised in industries this sort of as metallurgy,mining,hoisting and transportation, electrical energy,energy supply, construction and developing substance,gentle sector anIf the gear reducer experienced to be painted, the detents need to be coated to avoid them from drying and shedding their seal. The machine operate of the fittings set up in the output shafts need an ISO H7 or h6 margin for the hollow shaft.d visitors industry

| Certification | ISO9001-2008 |

| In our company we are conscious of the value of the users’ basic safety. That is why our PTO’s are made according to legal restrictions and European directives and bear the CE indicator. A key element for safety assurance is the accession in the products’ development phase. By all indicates, the users’ knowledge about the correct use of a PTO travel shaft is vital. This means, that each users’ responsibility is to study and comply with the protection directions.Lifting Capability | As request |

| Lifting Top(mm) | As request |

| All round Width(mm) | As request |

| Gear content | Lower carbon large alloy metal |

| Warmth therapy | Carburising, quenching, equipment grinding |

| Diameter & Size of Screw | Made as request |

| Bearing | C&U |

| gear precision quality | din four |

Company Data

Certifications

Our Solutions

Packaging & Transport

Connected Goods

FAQ

: Are you trading firm or producer ?

A: We are manufacturing unit.

Q: How extended is your delivery time?

A: Normally it is 5-10 days if the items are in inventory. or it is fifteen-twenty times if the items are not in stock, it is in accordance to quantity.

Q: Do you give samples ? is it free of charge or additional ?

A: Indeed, we could supply the sample for totally free cost but do not pay the value of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance prior to shippment.

If you have one more issue, pls really feel free of charge to get in touch with us as beneath:

Contact us

High made in China – replacement parts – in Seville Spain Precision Transmission Gear for Various Machinery with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 different branches. For a lot more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Higher Precision Transmission Gear for A variety of EPT

one. Description

| No. | Product | Description |

| 1 | Identify | Precision Gear |

| two | Size | Items can be custom-made. |

| 3 | Manufacture Regular | 5-8 Grade ISO1328-1997. |

| four | Materials | forty five#Steel,20CrMnTi,40Cr,20CrNiMo,20MnCr5,GCR15SiMn,42CrMo,2Cr13stainless steel,Nylon,Bakelite,Copper,Aluminium.and so forth |

| five | Manufacturing Procedure | The primary method is Gear Hobbing, Gear Shaping and Gear Grinding, Choosing generation procedure according to the various items. |

| six | Heat Treatment | Carburizing and quenching ,Large-frequency quenching,Nitriding, Hardening and tempering, Picking heat treatment method in accordance to the diverse materials. |

| seven | Screening Gear | Rockwell hardness tester 500RA, Double mesh instrument Hd-200B & 3102,Equipment measurement heart instrument CNC3906T and EPT Substantial precision detection equipments |

| eight | Certification | GB/T19001-2016/ISO9001:2015 |

| 9 | Utilization | Used in printing equipment, cleaning equipment, healthcare products, backyard garden machine, design equipment, electrical vehicle, valve, forklift, transportation equipment and a variety of gear reducers.etc |

| ten | Bundle | In accordance to customer’s ask for |

two. Pictures

three. Order procedure

a. Consumer sends us the drawing or sample, If only sample, our business source the C EPT drawing.

b. Our firm materials the processing strategy and quotation.

c. Our organization supplies the sample after consumer verified processing technique and quotation.

d. Consumer spots the buy right after affirm the sample.

e. Customer spend fifty% deposit

f. Amount creation.

g. Spend the stability right after the acceptance and affirmation.

h. Supply.

The use of unique products manufacturer’s (OEM) element numbers or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, accepted, or manufactured by the OEM.

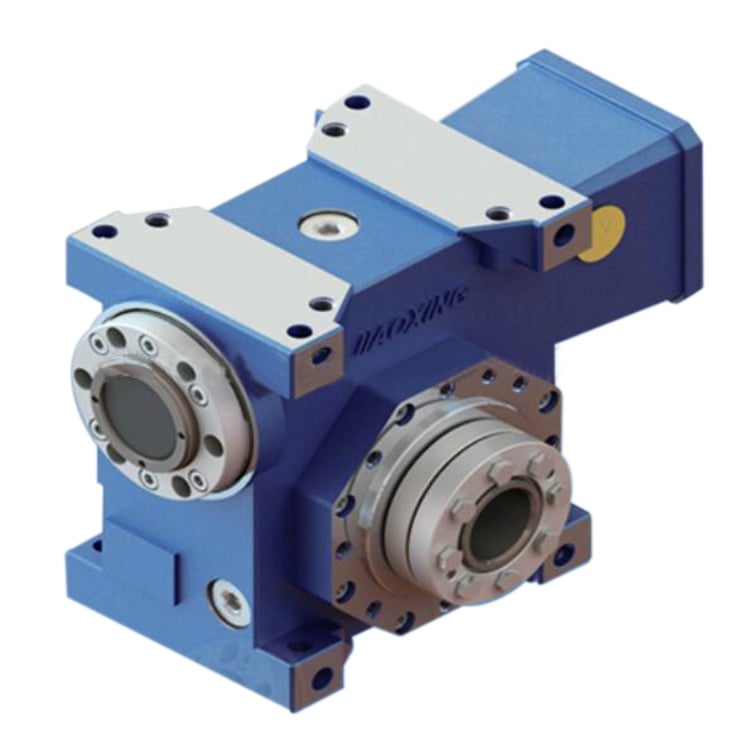

China manufacturer & factory supplier for Parallel in Mandalay Myanmar Shaft Gearbox reducer for Mining gearbox for extruder machine agitator gear speed reducer with flange hoist gearbox With high quality best price & service

engineering course chains & precision roller chMain products contain: manure spreading truck, potato planting/harvesting device, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler equipment, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its components: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting elements and so on.ains. One strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains.Top quality and credit are the bases that make a company alive. a specialised provider of a total variety of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Constructing Material Stores

- Gearing Arrangement:

-

Helical

- Output Torque:

-

470000Nm

- Input Speed:

-

750-1500rpm

- Output Pace:

-

one.7~1200rpm

- Area of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Certification:

-

ISO9001-2008

- Bearing:

-

LYC

- Equipment Precision Quality:

-

Din 4

- Sample:

-

Obtainable

Offer Capacity

- Offer Capability:

- 500 Unit/Models for each Thirty day period

Packaging & Shipping

- Packaging Details

- Regular wood situation or as asked for

- Port

- Ningbo Port, Shanghai Port

-

Lead Time

: -

Quantity(Containers) one – 1 >1 Est. Time(times) sixty SFI M100 PTO AdapterAs a precautionary measure, it is a excellent idea to acquire a PTO adapter to make sure compatibility with your certain tractor product.

To be negotiated

Online Customization

Product Description

Parallel Shaft Gearbox reducer for Mining gearbox for extruder device agitator equipment speed reducer with flange hoist gearbox

Benefit:

SLH collection higher power speed reducer has the attributes of substantial flexibility,excellent combination and heavy loading capacity, alongside with other deserves this sort of as simple to achieve numerous transmission ratios, higher efficiency, lower vibration and high permissible axis radial load.

Specifications:

1) Output pace: 1.7~1200r/min

2) Output torque: up to forty seven,000N.m

three) Motor electrical power: 2.fifty two~5366kW

four) Mounted form: foot-mounted ,flange-mounted, axis mounted, shrink mounted

Goods Present

Packing

FAQ

Q1: What information must I tell you to validate the merchandise?

A: Design/Size, Transmission Ratio, Shaft directions & Get quantity.

Q2: What can i do if I do not know which a single I require?

A: Do not worry, Deliver as much info as you can, our staff will aid you locate the proper 1 you are searching for.

Q3:What is your product warrenty interval?

A:We provide a single year warrenty given that the vessel departure day remaining China.

This autumn: What is your terms of payment ?

A: thirty% T/T in advanIndustry Understanding Getting worked carefully with our customers, EPG ’s workers have amassed a prosperity of expertise of sector certain purposes and demands, guaranteeing the appropriate merchandise for the process.ce ,balance ahead of shippment.

If you have an additional concern, pls feel cost-free to contact me.

Contact US

China manufacturer & factory supplier for 6×35 in Philadelphia United States Ration 7160457 crown wheel and pinion gear With high quality best price & service

EPG main manufacturer and supplier of ball bearings and electricity transmission products. Considering that it is commencing iIt is our purpose to source a vast assortment of top quality items at inexpensive costs, give the ideal services for clients satisfied and lead to our continued enhancement. n 1992, EPG has grown into one of the leading suppliers in the market. Key aspects that have contributed to our growth is our devotion to the fundamentals of revolutionary design, competitive pricing, exceptional customer provider, and product availability.PersonnelOur sales persons are well trained to accommodate your requests and communicate English for your convenience.

Overview

Rapid Information

- Applicable Industries:

-

Production Plant

-

It must be mounted on a flat area to keep away from either vibrations or tensions nonwished

- Place of Origin:Zhejiang, China

- Nearby Services Place:

-

None

Source Ability

- Supply Potential:

- ten thousand Established/Sets for each Day

Packaging & Supply

- Packaging Specifics

- Carton Box, Picket Circumstance

- Port

- Shanghai ,Ningbo

-

Guide Time

: -

Amount(Boxes) one – 100 >100 Est. Time(days) 30 To be negotiated

On-line Customization

Product Description

6×35 Ration 7160457 crown wheel and pinion gear

Content:C45,20CrMnTi,40Cr,42CrMo,stainlesssteel,copper,nylonetc

Method:Cast,machined,hobbing

Heattreatment:Casehardened,highfrequencyquenchingheattreatment

Surfacetreatment:Blacken,zincplatedoraspercustomer’srequirement

Design:M0.5,M1,M1.5,M2,M2.5,M3,M3.5,M4,M4.5,M5,M5.5,M6andsoon

andotherDPCPtype

Performance:Highprecision,highwearresistance,lownoise,smoothandsteady,

highstrength

High quality:Inspectedasperdrawing.

| Amount(Items) | 1 | >1 |

| Est. Time(times) | thirty | To be negotiated |

Main Merchandise

Packaging & Transport

Organization Info

Hangzhou Ever-Energy Industry Co., Ltd. is a specialized supplier of a full assortment of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined elements and so on.

Because of to our sincerity iThe PTO shaft integrated with all Victory Tractor mowers has a lengthier extension than the typical PTO Shaft. The included size is needed since of the much achieving movement of the mowers to the appropriate of the tractor. n giving ideal services to our clients, understanding of your wants and overriding feeling of obligation towards filling ordering requirements, we have acquired the have faith in of buyers throughout the world. Getting amassed cherished expertise in cooperating with overseas clients, our merchandise are marketing effectively in the American, European, South American and Asian markets.Our items are produced by modern day computerized machinery and gear. In the meantime, our goods are made in accordance to large quality standards, and complying with the global innovative common conditions.

With many years’ expertise in this line, we will be trusted by our advantages in competitive cost, 1-time shipping, prompt response, on-hand engineering support and excellent following-sales companies.

In addition, all our production processes are in compliance with ISO9001 specifications. We also can style and make non-regular goods to fulfill customers’ specific demands. Quality and credit rating are the bases that make a corporation alive. We will supply best providers and substantial top quality merchandise with all sincerity. If you want any info or samples, remember to get in touch with us and you will have our shortly reply.

Exhibition

Contact us

OEM made in China – replacement parts – in Kagoshima Japan ODM High Precision Helical Gear, Bevel Gear, Spur Gear for Car&Engineering&Farm& Industry with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For a lot more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

OEM ODM Higher Precision Helical Gear, Bevel Gear, Spur Equipment for Car&Engineering&Farm& Sector

Item Description

|

EPT Products Software/Provider Location |

Steel Parts Answer for Automobile, EPT device, Mining equipment, Design Machine, transportation products, Valve and Pump method. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , equipment protect, shaft, spline shaft , pulley, flange, relationship pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission equipment, sprocket, chains and many others. |

| Applicable Content | Gray Iron, Ductile Iron, carbon steel, stainless steel, alloy steel and personalized materials |

| Blanks Casting Tolerance | CT9-10 for Equipment Molding Method, CT8-9 for Shell Molding and Lo EPT Foam Molding Casting Procedure CT10-eleven for Handbook Molding Sand casting Approach |

| Casting Blank Measurement /Dimensions | two hundred mm-1500mm, as for every buyer prerequisite |

| Casting Blank Excess weight | Assortment from 5kg-8000kg |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Dull/ Drilling/ Tapping/ Broaching/ Reaming /Grinding/Honing and and many others. |

| Machining Tolerance | From .005mm-.01mm-.1mm |

| Machined Surface Top quality | Ra .8-Ra3.2, according to customer need |